Guide to Irrigation Sprinkler Packages for Pivots and Laterals

Almost everything in agriculture is becoming high speed, high tech, and high performance. From seed genetics to combine harvesters, the engineering in farming has become extensive and often expensive. In irrigated agriculture, there is a piece of equipment that tacks on more hours than any other piece of machinery on the farm. It drives in circles and never gets fancy green or red paint, but the often-overlooked center pivot plays a vital role in crop health and yield. Pivot technology has continued to surge ahead with the rest of agriculture, but simply having the optimal sprinkler package may be the best investment for this critical piece of machinery.

On-Farm Testing

Since the beginning of 2018, researchers at Utah State University (USU) have been evaluating the performance of several pivot sprinkler packages. This work has been conducted on commercial and university-owned farms across the state to attain data relevant to many soil types and crops (Table 1). At each farm, entire tower-to-tower spans of the irrigation pivot or lateral were outfitted with a designated sprinkler package. Over the course of the growing season, we monitored soil moisture, measured crop yield, and analyzed crop samples for quality.

|

Table 1 |

||||

|

Nearest town |

Years |

Dominant soil texture |

Water storage per foot of soil |

Slope |

|

inches |

% |

|||

|

Logan |

2019–2020 |

Loam |

2.2 |

0 – 3 |

|

Elberta |

2018–2019 |

Silt loam |

2.1 |

1 – 2 |

|

Vernal |

2020 |

Clay loam |

2.0 |

0 – 2 |

|

Cedar City |

2018–2020 |

Sandy loam |

1.7 |

0 – 2 |

Research performed at Elberta and Cedar City was a collaborative effort with private farmers and ended in 2020. The Logan and Vernal field trials are part of a long-term water optimization project evaluating sprinkler packages, tillage practices, cover crops, wetting agents, and drought tolerant genetics. In the spring of 2021, research will start in Cedar City at another state-owned farm, with a similar design to Logan and Vernal. Forthcoming results from these studies will be available through the USU Extension crops team. The following four irrigation systems were evaluated in on-farm testing: mid elevation sprinkler application (MESA); low energy precision application (LEPA); low elevation spray application (LESA); and mobile drip irrigation (MDI). Specifications and a cost range of each system are provided for comparison. The costs listed account for clamps, fittings, hoses, nozzles, regulators, sprinkler heads, and other supplies specific to each system. Installation labor is not included. Outlet spacing on the pivot is an important cost factor when adopting a design with closer spacing. The efficiencies shown with each system are approximates measured in previous research (Amosson et al., 2011; Oker et al., 2020).

Mid Elevation Sprinkler Application (MESA) 78% Efficient

- Most common current system on pivots in northwestern United States.

- Rotating parts produce a circular pattern.

- Many throw patterns and angles to choose from.

- 20–75 foot wetting diameter.

- 3–6 foot installation height above the soil surface.

- 7.5–20 foot spacing between drops

- $4,500–$6,000 for a 1300–pivot (125 heads; $38–50/acre for 120 acres).

Low Energy Precision Application (LEPA) 95% efficient

- Common in water-scarce regions of the South.

- Bubblers, accelerators, plates, deflectors, and drag socks are available to tailor applications.

- 1–2 foot installation height above soil surface.

- 2.5 to 3.5 foot spacing between drops.

- $9,000–$14,000 for a 1300-foot pivot (325 heads) with first 2 to 3 spans being MESA ($75–$117/acre for 120 acres).

Low Elevation Spray Application (LESA) 88% efficient

- Spray pattern of individual streams.

- Pattern angle and coarseness customizable.

- 12–30 foot wetting diameter.

- 1–3.5 foot installation height above soil surface.

- 4.5 to 5 foot spacing between drops.

- $6,000–$8,000 for a 1300-foot pivot (250 heads) with the first 2 spans MESA ($50–$67/acre for 120 acres).

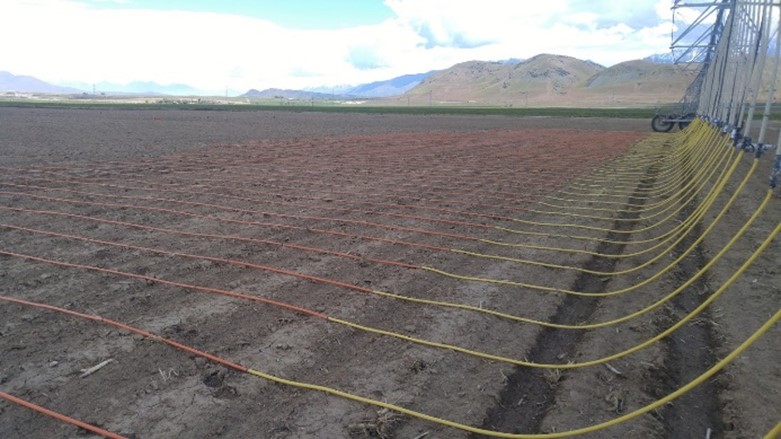

Mobile Drip Irrigation (MDI) 97% efficient

- Drip tubing pulled from a pivot-mounted manifold.

- MESA heads for germination and chemigation.

- Drip tape length is adjusted to set rates.

- 1–2 gallons per hour emitters every 6 inches.

- 2.5 to 3.5 foot spacing of drip lines.

- Automated filter recommended (about $14,000 but can generally service more than one pivot).

- $20,000–$30,000 for a 1300-foot pivot ($167–$250/acre for 120 acres with no filter included).

Previous studies on LEPA, LESA, and MDI have shown that they can be up to 19% more efficient at placing water in the root zone than MESA (Amosson et al., 2011; Oker et al., 2020), or in other words, from the time the water leaves the nozzle or drip tubing, 19% less is lost to evaporation and wind drift. Our evaluations sought to determine if these increased efficiencies meant these systems could grow a comparable crop while applying less total water. The theory is simple; if these systems have less loss than MESA, then reducing the rate should still mean the same amount of water will be available in the rootzone for plant growth. If enhanced efficiency can translate to less irrigation without lost production, it would help growers reduce energy costs and help their water allotment go further. To test this theory, our test spans with LEPA, LESA, or MDI all had part of the span with the same design rate as the MESA, and a part of the span designed to apply 20–30% less, as depicted by the rows labeled “reduced” in Tables 2 and 3.

|

Table 2 Yield Differences of Various Irrigation Systems Shown as % Difference from MESA Yield for On-Farm Trials in Cedar City and Elberta, Utah |

||||||

|

Irrigation System

|

Cedar City |

|

Elberta |

|||

|

2018 Alfalfa |

2019 Alfalfa |

2020 Alfalfa |

2018 Silage corn |

2019 Silage corn |

||

|

MESA (tons/acre) |

4.0 |

6.4 |

4.9 |

27.2 |

23.5 |

|

|

LEPA |

0 |

-10% |

-28% |

0 |

0 |

|

|

LEPA reduced 20% |

-12% |

-18% |

-22% |

0 |

-13% |

|

|

LESA |

. |

. |

. |

0 |

0 |

|

|

LESA reduced 20% |

. |

. |

. |

. |

0 |

|

|

MDI a |

-13% |

-9% |

-11% |

. |

0 |

|

|

MDI reduced 30% |

-24% |

-22% |

-35% |

0 |

-13% |

|

|

Full rate applied (inches)b |

26.4 |

23.5 |

26.6 |

|

30.2 |

30.8 |

Note. Average of four yield measurements per treatment. Only statistically significant differences at a confidence level of 95% are shown. “0” denotes there was no difference in yield from MESA. Percent reductions are as designed and may vary from the actual output.

aAt Cedar City in 2018, the “MDI” applied 40% less than designed and “MDI reduced 30%” was actually reduced by 60%. bFull rate application measured in MESA.

|

Table 3 |

|||||||

|

Irrigation System |

Logan |

Vernal |

|||||

|

2019 Silage corn |

2020 Silage corn |

2020 Alfalfa |

2020 Silage corn |

2020 Small grain forage |

2020 Teff |

||

|

MESA (tons/acre) |

26.2 |

39.8 |

3.1 |

33.8 |

2.9 |

2.9 |

|

|

LEPA |

0 |

-10% |

0 |

+13% |

0 |

0 |

|

|

LEPA reduced 25% |

0 |

0 |

0 |

0 |

0 |

0 |

|

|

LESA |

0 |

-16% |

0 |

+10% |

0 |

0 |

|

|

LESA reduced 25% |

-14% |

0 |

0 |

+10% |

0 |

0 |

|

|

MDI |

0 |

-13% |

0 |

-26% |

-44% |

-77% |

|

|

MDI reduced 25% |

0 |

. |

-41% |

-30% |

0 |

-80% |

|

|

Full rate applied (inches)a |

13 |

13 |

13.8 |

|

27.2 |

14.7 |

12.3 |

Note. Average of four yield measurements per treatment. Only statistically significant differences at a confidence level of 95% are shown. “0” denotes there was no difference in yield from MESA. Percent reductions are as designed and may vary from the actual output.

aFull rate application measured in MESA.

Results and Observations

Results obtained in these studies were variable—no system came out on top as the best choice. We did not determine that any one of these packages could maintain yield at a reduced rate, all the time, in all crops, and in all fields. In fact, sometimes there was no benefit to the advanced systems, yet in other situations, they performed just as well as MESA while applying less water. What we did figure out, was a lot of information that can help guide farmers when making decisions on when and where they might invest in LEPA, LESA, and MDI. Crop selections, water quality, pumping capacity, prevailing winds, topography, and soil type are some of the important field variables that need to be factored into the decision. Another important aspect is the level of potential for water shortages. Installing an advanced system may not always impact yield in a year with normal precipitation. However, if a few seasons of water shortage are expected over the useful life of the sprinkler package, a higher efficiency system may be worth it just for those times.

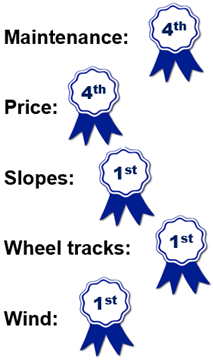

Following is a review of some advantages and disadvantages of each system, based off data, observations, and experiences working with them. Five factors highlighted are maintenance, price, slopes, wheel tracks, and wind. These, and other factors like evaporation or pest control, all come with trade-offs. A small wetting area from closely spaced heads will reduce effects from wind drift and evaporation yet can result in runoff or extra maintenance. Meanwhile, a large wetting area will reduce runoff by allowing more time for water infiltration but may incur greater losses to evaporation or poor uniformity due to wind. The intent of this section is to help farmers find the best balance for their situation.

Mid Elevation Sprinkler Application.

This style of sprinkler package was the “control” of the studies, the system against which we were comparing the other systems. It is the least expensive, has the least amount of parts, and like the other systems, operates off low pressure to create large water droplets and reduce pumping requirements. The large wetting area is helpful in tight soils and mildly sloping fields, as longer time is given for irrigation to infiltrate the soil. The tradeoffs with having the water spread widely are deep wheels tracks and losses from wind and evaporation. In Elberta, wind caused a substantial yield drag on the southwest side of most fields. In situations like this, where persistent wind is a factor, MESA packages will usually have more distorted uniformity than the other packages.

The 2020 silage corn in Vernal (Table 2) was the only case out of 11 trials that one of the other systems yielded better than MESA at a full rate. This suggests that if water is not a limiting factor for an operation, this is a great choice. Ensuring that the nozzles, sprinklers, and regulators are not worn out is important to maintaining good uniformity, but depending on water quality, most sprinkler components can operate for at least 5000 hours before replacement. We often observed that wheel tracks caused by pivot or lateral tires were usually deeper for MESA than the other three systems because more water is applied to the track. This can cause more wear and tear on the pivot or linear and other machinery operating in the field. For those who have determined MESA is the best system for their application but are concerned with wheel tracks, the USU Extension crops team is performing research to improve this problem through simple and inexpensive design modifications.

Low Energy Precision Application

LEPA was introduced in 1981 (Lyle & Bordovsky, 1981) to combat water limitations and high energy prices. The close spacing, low sprinkler height, and low application pressure of this technology have had an impact on subsequent sprinkler developments. Retrofitting a pivot or lateral with widely spaced outlets is usually done either using simple truss rod clamps to space hoses or by using galvanized pipe, resulting in large price differences. When tripling the number of sprinkler drops on a pivot for LEPA, the nozzle sizes will be much smaller than MESA packages, which can sometimes lead to more nozzle plugging. Thus, we recommend that the first two to three inner spans of a pivot be equipped with MESA heads and spacing to alleviate this problem and avoid purchasing an expensive filtration system.

A benefit and detriment to these packages is the concentration of water in a small area. Being near the soil surface and wetting only a small diameter decreases the opportunity for water to be lost to evaporation or spread nonuniformly by the wind (Peters et al., 2019). The precision application also keeps the pivot and wheel tracks mostly dry, reducing the wear and tear on the pivot and other machinery. The downside to concentrating the water in such a small area is the potential to exceed the infiltration rate of the soil and produce runoff or surface movement (Peters et al., 2019). Due to the potential for this to occur with a LEPA package, they are not recommended for fields with slopes greater than 1% (Senninger Irrigation, 2018).

In all crops at the Logan and Vernal farms where a lateral was used, LEPA maintained yield when applying about 20% less irrigation than the MESA. Both fields have loamy soils that can store a good amount of water. In Cedar City, LEPA performed poorly at full or reduced rates. Alfalfa yield at this field was between 10 to 28% less with LEPA in the second and third year of the trial but was equivalent between MESA and LEPA in the first year (Table 2). This suggested that the negative impact of LEPA was growing with time. There was no clear reason why LEPA performed poorly at this field. One reason could be due to the placement of LEPA on this pivot. It was installed on the last span where uniformity can be more difficult to maintain, as the application rate per nozzle is nearly double that of the LEPA spans on the laterals, increasing the opportunity for ponding and surface movement. During irrigations, it was common to see ponded water in the LEPA. These observations led us to speculate that the yield drag was due to saturating the top foot of soil. This is something to be aware of when adopting LEPA, particularly near the end of the pivot where the application rate is highest. Optimal results for LEPA may require running the pivot faster than typical MESA applications to apply a smaller amount of water that will avoid ponding and runoff.

Low Elevation Spray Application

LESA sprinkler packages are a low risk, easy retrofit that also aims to decrease losses caused by evaporation and wind drift (Neibling, 2015; Swanson & Fipps, 2011). They do not eliminate these problems to the extent that LEPA or MDI can, but the risks are not as great either (Peters et al., 2019). Though intended to be near the ground, these heads have a large effective height range that can be tailored to work in fields with moderate slopes. Many similarities exist between LESA and LEPA, but there are some differences in how they perform, primarily in application patterns. LESA heads spray a large, flat circle of individual streams and attempt uniformity through close overlapping spray patterns. The diameter covered by each head depends on nozzle, plate, height, and pressure, but is usually between 12 to 30 feet. This results in less ponding and runoff than a LEPA system, yet it still is usually not an ideal system for sloping fields. One negative effect of the overlapping spray pattern is that it will get the wheel track wet and can produce deep wheel tracks like MESA.

In most of the situations where it was tested, LESA yielded just as good or better than MESA at full or a reduced rate, except in Logan, where it decreased silage corn yield by about 15% two years in a row. We are unsure of what caused the reduced yield. Still, it can serve as an example of the importance of selecting the right system and the wisdom of experimenting with only a span of a pivot if the decision is not clear-cut enough to make you comfortable changing the entire system.

Mobile Drip Irrigation

This technology has been around for several years, but there have been several improvements and new products on the market in the last five years. For pivots without close-spaced outlets, a horizontal manifold is attached to the pivot. This manifold can be fixed at a height specific for a crop, or an adjustable manifold is now available. Vertical, rigid drops come down from the manifold and can have a spray nozzle attached on the bottom for crop germination, chemigation, and fertigation purposes. A flexible length of hose is used to connect the manifold and drip tubing. Every six inches along the tubing are emitters, with water metering diaphragms. To prevent plugged emitters, careful filtration (minimum 80 mesh) is a necessity for these systems. Physical and biological contaminants such as sand, rust, algae, or bacteria can affect emitter performance. A water test is imperative before investing in a filtration system (for more details see “Mobile Drip Irrigation for Pivots and Laterals,” Yost et al., 2019). There is a component of added labor to be expected with the use of MDI as well. The drip lines need to be moved out of the way for field operations and should be protected from grazing livestock. Wildlife will occasionally test the durability of the drip lines, but these repairs are usually quick and inexpensive.

MDI may be the easiest system to rank. It is expensive, requires the most labor of any system, and has the most parts to maintain. However, it has shown some significant benefits (Molaei et al., 2020). Our research produced mixed results and many observations to help farmers know if they want to commit to MDI. In 2018, a design flaw with the drip tubing reduced the output of the emitters significantly in Elberta and Cedar City. At these two sites, irrigation rates with MDI were 40–70% less than MESA instead of our desired 20% reduction (Table 2). Despite drastically lower rates in MDI, it only decreased alfalfa yield by 24%. In the silage corn at Elberta in 2018, MDI yielded similarly to all the other systems with about 40% less water. We made corrections to the MDI for the 2019 growing season, which brought the output rates up to a similar range as the other systems. That year, it performed similarly to MESA while applying 15% less irrigation but would not sustain yield at a 30% reduced rate. This indicated an inconsistent ability of

MDI to maintain yield with less applied water than MESA. Alfalfa, silage corn, and small grain forage yields for 2020 showed reduced yields under all levels of MDI at all three fields where it was tested. In alfalfa, teff, and small grains, it was common to observe crop stunting in the area between the drip tubes. With soil moisture sensors and soil probes, we found that irrigation water would move laterally between the drip lines, but usually occurred about a foot deep, which may have been causing the crop stress. Wheel tracks are generally not a concern with MDI because no water is applied to the track, making MDI an excellent choice for improving track management. Areas where these systems may excel are in high value specialty crops, places with severe water restrictions, crops with large spacing, fields with steep slopes, or on a pivot with a dwindling well capacity.

MDI to maintain yield with less applied water than MESA. Alfalfa, silage corn, and small grain forage yields for 2020 showed reduced yields under all levels of MDI at all three fields where it was tested. In alfalfa, teff, and small grains, it was common to observe crop stunting in the area between the drip tubes. With soil moisture sensors and soil probes, we found that irrigation water would move laterally between the drip lines, but usually occurred about a foot deep, which may have been causing the crop stress. Wheel tracks are generally not a concern with MDI because no water is applied to the track, making MDI an excellent choice for improving track management. Areas where these systems may excel are in high value specialty crops, places with severe water restrictions, crops with large spacing, fields with steep slopes, or on a pivot with a dwindling well capacity. Summary

Research on 11 trials over three years has demonstrated that LEPA, LESA, and MDI can sometimes, but not always, maintain crop yield with about 20% less water than MESA. Thus, one system is not ideal for all scenarios and each field should be carefully assessed to determine which technology might be ideal for the good years and the bad. Compared to upgrading tractors or other farm equipment, it is relatively inexpensive to make changes to the sprinkler package of a center pivot. Determining which system is best for a particular field or application can be complex and often requires some on-farm experimentation. Testing a new sprinkler package on a single span of a pivot may be a smart way to see if a change will be effective for a field, and is a task easily carried out with a little math and some basic tools. Evaluations of investment (about $58, $96, $208/acre for LESA, LEPA, and MDI, respectively) in new sprinkler packages compared to MESA ($44/acre) should include:

-

Price difference (equipment and labor) between advanced and traditional packages.

-

Crop value change from advanced systems (increased or decreased yield and/or crop quality).

-

Changes to water productivity (e.g., greater infiltration, less losses through runoff, drift, and evaporation).

These assessments should be factored over the lifespan of a package (see manufacturer recommendations) and account for any anticipated water shortages. If more than the cost of the upgrade ($14–$164/acre, based on the cost of the various systems above) can be recovered over the lifespan of the package, then using advanced systems makes sense.

References

Amosson, S., Almas, L., Girase, J. R., Vimlesh, K., & Marek, T. (2011). Economics of irrigation systems. Texas A&M AgriLife Communications Extension publications, AgriLifeBookstore.org. https://cdn.agrilifetoday.tamu.edu/wp-content/uploads/2011/10/Irrigation-Bulletin-FINAL-B6113.pdf

Lyle, W. M., & Bordovsky, J. P. (1981). Low energy precision application (LEPA) irrigation system. Transactions of the ASAE, 24(5), 1241–1245. https://doi.org/10.13031/2013.34427

Molaei, B., Peters, R. T., & Kisekka, I. (2020). Mobile drip irrigation (MDI). Washington State University Extension. http://irrigation.wsu.edu/Content/Fact-Sheets/MDI.pdf

Neibling, H. (2015). Modification of center pivot irrigation systems with water-saving LESA technology. University of Idaho Extension. https://www.uidaho.edu/-/media/UIdaho-Responsive/Files/Extension/admin/Impacts/2015/29-15hneibling-LESA.pdf?la=en&hash=0303F9920F574EE63DC132774539A54D9D2430A2

Oker, T. E., Kisekka, I., Sheshukov, A. Y., Aguilar, J., & Rogers, D. (2020). Evaluation of dynamic uniformity and application efficiency of mobile drip irrigation. Irrigation Science, 38(1), 17–35. https://doi.org/10.1007/s00271-019-00648-0

Peters, T., Neibling, H., Stroh, R., Molaei, B., & Mehanna, H. (2019). Low energy precision application (LEPA) and low elevation spray application (LESA) trials in the Pacific Northwest. Oregon State University Extension. https://extension.oregonstate.edu/sites/default/files/documents/33601/lepa-lesa-pnw-stroh-revisions.pdf

Senninger Irrigation (2018). Staying close: The hot topic of LEPA close spacing irrigation. Potato Grower. https://www.potatogrower.com/2018/03/staying-close

Swanson, C., Fipps, G., & Nelson, A. (n.d.). LESA pivot sprinkler package comparison demonstration. Texas AgriLife Extension Service. https://itc.tamu.edu/files/2018/04/TAMU-Farm-LESA-Demo.pdf

Yost, M., Holt, J., Reid, C., Winward, D., Allen, N., & Creech, E. (2019). Mobile drip irrigation for pivots and laterals. Utah State University Extension. https://digitalcommons.usu.edu/cgi/viewcontent.cgi?article=3011&context=extension_curall

*All photos by the authors.

Published February 2021

Utah State University Extension

Peer-reviewed fact sheet

Authors

Jonathan Holt, Matt Yost, Niel Allen, Earl Creech, Dean Winward, Tina Sullivan, and Boyd Kitchen

Related Research