Chemigation Guide

Introduction

Chemigation is the application of agrochemicals to soil or crops through an irrigation system. Chemigation can include agrochemicals like fertilizers (fertigation), fumigants (fumigation), pesticides and their surfactants and adjuvants (fungigation, herbigation, insectigation). Chemigation is an alternative option to aerial and ground agrochemical application and can be an effective method of applying agrochemicals without increasing field traffic, especially when crop height restricts ground applications. The majority of chemigation that occurs in Utah is fertigation. For detailed information about best fertigation practices see a companion fact sheet (Egbert et al., 2020). Other types of chemigation besides fertigation are also used in Utah. This guide will discuss general principles that will apply to most types of chemigation applications.

Pros and Cons of Chemigation

The pros and cons of chemigation can be quite complex and variable among farm operations and irrigation systems. The following table outlines some major factors one might consider when deciding whether to start or continue chemigation.

| Pros | Cons |

| Uniform application. | Application uniformity is only as uniform as the irrigation application. |

Reduced chemical exposure to the applicator. |

Initial investment in equipment, and liquid fertilizers can cost more than solid forms. |

| Saved time and labor. | Additional technical expertise required to install and maintain equipment. |

| Reduced fuel and equipment cost. | Increased wear and tear on irrigation systems leading to greater irrigation equipment costs. |

| Flexible timing for agrochemical applications, especially at late crop growth stages. | Delay in application if irrigation is delayed by rain or adverse weather conditions. |

| Less wheel tracks, soil compaction, and crop damage from mechanical ground equipment. Incorporation of agrochemicals to a required depth leading to immediate activation within the soil. |

Additional non-uniformity in applications when irrigation equipment issues arise. |

| The ability to “spoon-feed” nutrients all season and/or apply nutrients at critical growth stages. Not only can this improve crop performance, it also can reduce loss of nutrients to leaching, runoff, volatilization and other loss pathways. | Risk of water source contamination. |

| Well suited for no till systems. | Potential environmental pollution because of drift and runoff. Longer application times according to speed of irrigation system delivery. |

| Adverse chemical reactions leading to the formation of precipitates. |

Pre-Chemigation Checklist

In order to prepare for safe and effective chemigation, some of the major steps include:

- Inspect and perform maintenance on irrigation systems to ensure proper functionality and uniformity. If uniformity is low and cannot be remedied, chemigation is not recommended (see Topper et al. 2010 for more details).

- Ensure that all irrigation protective equipment and safety measures are intact and functional (see Stamper et al., 2018 for more details).

- Determine whether irrigation water leaves the field as drainage or runoff, or whether irrigation systems apply water into the water source (for example, center pivot crossing a canal or ditch). Be aware that chemigation could influence downstream or offsite users (see Bauder, 2009 for more details).

- Consider the location of the application site relative to sensitive sites (such as groundwater or drinking water supplies). Agrochemical labels will generally detail restrictions and warnings.

- Review soil properties, topography, and geological features that could potentially cause issues.

- Evaluate whether purchasing or leasing chemigation equipment is more economical.

- Read and follow label requirements for licensing, personal protection equipment, and proper reentry documentation.

- Review best management practices and regulations for chemigation.

Utah Law and Regulation

Although agrochemicals are a potential non-point contamination source, Utah does not currently enforce laws or regulations for agricultural chemigation. The State has published best management practices for chemigation that will help ensure safe and proper chemigation management (State of Utah Department of Environmental Quality, 2013). Chemigation is, however, regulated by the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), which is enforced by the Environmental Protection Agency (EPA). Federal regulation requires safety measures and devices (for example, backflow prevention) to be in place to protect source water from contamination.Agrochemical handling is the same for chemigation as for any other type of application. Applicators are subject to the Worker Protection Standard (WPS) requirements of all agrochemical labels. In addition to the WPS, all chemicals used for chemigation are subject to the agricultural use requirements. Many agrochemicals are classified as general use and would not require a license for application. Any restricted use chemicals would require an applicators license. If the label makes no reference to chemigation or states, “Do not apply this product through any type of irrigation system” it cannot be used for chemigation.

Chemigation Setup

The two most common irrigation systems where chemigation is practiced in Utah include pivots and gravity irrigation. When used in furrow/flood irrigation, agrochemicals are simply dripped into the water, typically in a ditch shortly before the water is applied to the field. When used with pivots, agrochemicals are most commonly injected into the irrigation water at the base of the pivot.

Chemigation setup for pivots can vary widely, but nearly all will contain these four basic components:

1. Stock solution tank.

2. Hoses or pipes to transfer the agrochemical solution.

3. Injector and pump to get the agrochemical into the irrigation water.

4. Backflow prevention devices and other safety equipment (USDA-NRCS, 1997)

Some major details of components three and four will be described below.

Some major details of components three and four will be described below.

Chemigation Injection Methods

There are several methods available for injection of agrochemicals. Haman and Zazeuta (2017) describe in detail 11 separate methods for injection, along with a summary of the advantages and disadvantages of each (see Table 1 in Haman and Zazueta, 2017). Because these authors have provided comprehensive descriptions of the various methods, our discussion will briefly outline three of the main categories of injectors, along with basic functions and applications.

1. Pressure Differential

- Pressure and small portion of flow siphoned off main line into tank, water mixes with and dilutes stock solution from tank back into main line.

- Not well-suited to self-moving sprinklers (pivots and linears) since concentration of fertilizer is not constant. Used for solid set, side-roll and drip systems.

- Designed to deliver set amount of material to a specific area over time

2. Venturi

- Pressure differential caused by flow restriction through injector causes suction to draw fertilizer material into main line.

- Concentration more stable over time, but may vary with pressure fluctuations in system (friction requires accounting for pressure loss in system)

- Designed to deliver target concentration of material for a specified length of time to an area

3. Positive (or direct) displacement

- Electric, gas or hydraulic pump-type injector that precisely meters fertilizer stock into main line

- Concentration very stable over time (hydraulic injectors are rhythmic directly with main line flows)

- Designed to deliver set concentration of material for a specified time to an area

Of these three injection methods, there are three types that are used most commonly for chemigation in agriculture. These include venturi injectors plus two types of positive displacement pumps (piston and diaphragm):

- Venturi injectors – are typically the least expensive and simplest option, but make it more difficult to maintain consistent injection rates and are typically less adjustable than other pumps.

- Piston pumps – are usually more expensive than venturi pumps, but offer a wider range of injection rates. They can be hard to accurately calibrate and are more likely to wear out quickly where they come into contact with agrochemical.

- Diaphragm pumps – have few moving parts, are less subject to wear and corrosion, and are more easily calibrated and adjusted than other pumps. Overall, they are the best pumps but are also typically the most expensive option (Hiller, 1995).

Backflow Prevention

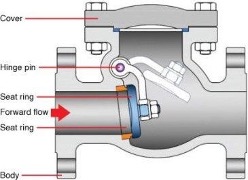

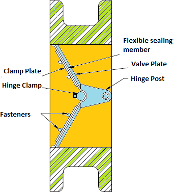

Several safety measures are required for proper chemigation. These include can include interlock, low pressure drain, backflow valve, inspection port, check values, and chemical resistant hose and clamps (USDA- NASS, 1997). One of the most important safety components of chemigation systems is backflow prevention. Backflow is the movement of agrochemicals in the reverse direction towards the source water.

Backflow can occur in two ways, back-siphonage and back-pressure. Back-siphonage occurs when the pressure in the main line is less than atmospheric pressure. The difference in pressure causes a partial vacuum that pulls on the system. As the water is pulled back towards the source, the created vacuum pulls on all cross connections and inevitably sucks the agrochemical through all the connections. Back-pressure occurs when the irrigation system operates at a higher pressure than that of the supply water system. Back-pressure also occurs when multiple systems are interconnected by a main line and are operating at different pressures.

Backflow prevention devices, such as check valves, are important for two major reasons:

- A backflow prevention device placed before the injection point on the irrigation water line will prevent the agrochemical from flowing back into the water source and contaminating it. This is especially important when the water source is a well because any agrochemical backflow will contaminate the groundwater (Bauder, 2009).

- A second backflow on the injection line will prevent irrigation water from being able to flow back into the solution tank. This will prevent either flooding or contaminating the stock tank (Carpenter et al., 2007).

Selecting Chemigation Mixes

The first step in selecting chemigation mixes is to consult agrochemical labels. If a label does not indicate that an agrochemical is registered for application with irrigation, do not chemigate with that product. Product labels will often state whether and which products can be mixed. In the event that the label does not provide any tank-mix instructions or restrictions, then responsibility of performing a “Jar Test” falls on the applicator.

The Jar Test helps the applicator to determine physical and chemical compatibility between two or more materials (including one chemical and irrigation water). This is especially important when mixing more than one agrochemical. It is also usually pertinent even when agrochemical labels do provide details on appropriate mixes to ensure the chemicals are compatible with the irrigation water, especially when degraded irrigation water is used. Many common fertilizers, otherwise soluble in a given water, may precipitate in the presence of other chemicals. Two examples of incompatibilities include:

- Ammonium phosphate liquid fertilizer (highly soluble in water) can react rapidly in high pH, hard water to form ca-mg-phosphate, or apatite, a highly insoluble precipitate that can clog lines, nozzles and drippers.

- Urea hydrolysis can increase pH of alkaline water to values above 8.0, and render soluble iron in water, insoluble and form iron carbonates in sprinkler nozzles and drippers.

To complete a jar test:

- Collect a sample of the water (at temperature directly from irrigation source) that will be used for the chemigation. Mix desired agrochemical(s) at the correct concentrations.

- Wait several minutes then watch for any signs of incompatibilities. Physical incompatibility may result in the formation of gels, foams, and precipitates. Chemical incompatibilities are much more difficult to detect. Some chemicals act synergistically and others weaken each other’s efficacy.

- If you have the ability and time, it may be wise to apply the mixture to the target crop to ensure no crop damage occurs.

Setting Chemigation Rates

Consult the agrochemical label first for instructions. Labels almost always contain a table that shows how much chemical to use for a given concentration and for a range of injector ratios. This tells you what injection rate to use for your fertilizer concentration so you can apply the desired amount of fertilizer.

If the concentrations and injector ratios you desire to use are not on the label, then use the desired concentration, injector ratio, dilution factor, active ingredient rate, and the number of ounces of agrochemical to make one gallon of stock solution to calculate the correct amount of chemical to use (Stivers, 2015).

Two methods to calculate include:

- The easiest way to do these calculations is to use an online or phone app calculator. One example of these is Dosatron’s Stock Tank Solution Calculator for Water-Soluble Powder (dosatronusa.com/calculators/WatersolublePowd erCalc.autocalcoff).

- If online calculators do not accommodate your situation, the calculations can always be done by hand (see Penn State Extension “How to Mix a Stock Fertilizer Solution for injectors” to learn how to do the calculations by hand extension.psu.edu/how-to-mix-a-stock-fertilizer- solution-for-injectors).

This practice can reduce the chance of over or under applying agrochemicals.

Summary

When best management practices are followed using irrigation systems with high uniformity on non-sensitive fields, chemigation is typically an excellent way to add flexibility, split or more precisely time chemical applications, reduce soil compaction and crop damage, and reduce labor for irrigated agriculture.

Resources and References

Bauder, T. 2009. Pesticide mixing and loading and your family’s water supply. From the Ground Up: Agronomy News. Vol. 28 Issue 2. Colorado State University Extension. http://www.extsoilcrop.colostate.edu/Newsletters/d ocuments/2009/2009_may.pdf.

Carpenter, J., and W.S. Johnson. (2007). Pesticide Chemigation Through Pumped Irrigation Systems. University of Nevada. Available at https://www.unce.unr.edu/publications/files/ag/othe r/fs9737.pdf (verified 30 Dec 2019).

Dosatron. Stock Tank Solution Calculator for Water- Soluble Powder. Dosatron. Available at https://www.dosatronusa.com/calculators/Watersolu blePowderCalc.nonfert/WatersolublePowderCalc.n onfert.htm (verified 30 Dec 2019).

Haman, D.Z., and F.S. Zazueta. 2017. Chemical injection methods for irrigation. University of Florida Extension. CIR864. https://edis.ifas.ufl.edu/pdffiles/WI/WI00400.pdf

Hiller, J., M. Ferrell, and A.M. Lewis. 1995. Chemigation Equipment and Calibration Procedures. University of Wyoming Extension. Available at https://www.uwyoextension.org/psep/wp- content/uploads/2012/09/B-1023.pdf (verified 30

Dec 2019).

MegaDepot. 2015. A Guide to Types of Valves.

MegaDepot. Available at https://megadepot.com/resource/a-guide-to-types- of-valves (verified 30 Dec 2019).

Porter, W. 2015. Pivot set up for fertigation. Seminole Crop News. Available at https://seminolecropnews.wordpress.com/2015/05/0 7/injecting-through-the-pivot/ (verified 30 Dec 2019).

Stamper, J., J. Wright, F. Bergsrud, and J. Peckham.2018. Chemigation safety measures. University of Minnesota Extension. https://extension.umn.edu/irrigation/chemigation- safety-measures#low-pressure-shutdown-switch- 1022363

State of Utah Department of Environmental Quality Division of Drinking Water, 2013. Ground water source protection user’s guide. Salt Lake City, Utah.

Stivers, L. 2015. How to Mix a Stock Fertilizer Solution for Injectors. Penn State Extension. Available at https://extension.psu.edu/how-to-mix-a-stock- fertilizer-solution-for-injectors (verified 30 Dec 2019).

Topper K.A., T.F. Tindall, and D.W. James. 2010. Field Crop. Utah Fertilization Guide. Utah State University Extension. Pgs. 20-22. Available at https://extension.usu.edu/waterquality/files- ou/Agriculture-and-Water-Quality/Fertilizer/AG- 431.pdf (verified 30 Dec 2019).

USDA-National Resource Conservation Service (NRCS). 1997. Chemigation. National Engineering Handbook Series. Irrigation Handbook. Ch. 7 pgs 207-219. Available at https://directives.sc.egov.usda.gov/OpenNonWebC ontent.aspx?content=17837.wba

Revised February 202 and published to the Web May 2022

Utah State University Extension

Peer-reviewed fact sheet

Authors

Matt Yost, Grant Cardon, Niel Allen, Bryce Sorensen, Kyle Egbert, Earl Creech, Corey Ransom, and Ricardo Ramirez

Utah State University Specialists

Related Research