Principles of Pressure Canning

Why Choose Pressure Canning to Preserve Food?

Pressure canning is a safe and economical method of preserving low acid foods which has been used for decades—especially by home gardeners and others interested in providing food storage for their families where quality control of the food is in ones’ own hands. Home food preservation also promotes a sense of personal satisfaction and accomplishment. Further, the guess-work is taken out of being able to provide a safe food supply at home when guidelines for operating a pressure canner are followed exactly, scientifically tested/approved recipes are utilized, and high quality equipment, supplies and produce are used.

What Foods Are Typically Processed/Preserved Using a Pressure Canner—and Why?

Low acid foods require a higher temperature when processing than can be reached by placing them in jars immersed by boiling water. To kill harmful bacteria (such as those associated with botulism) use of pressure canning ensures the safety of preserved low-acid foods. Foods such as red meats, seafood, poultry, dairy, and all fresh vegetables, with the exception of most tomatoes, fit into the low acid group since they have an acidity, or pH level, of 4.6 or higher. The temperature which must be reached and maintained (for a specified amount of time) to kill the bacteria is 240o F. This temperature can be reached only by creating steam under pressure.

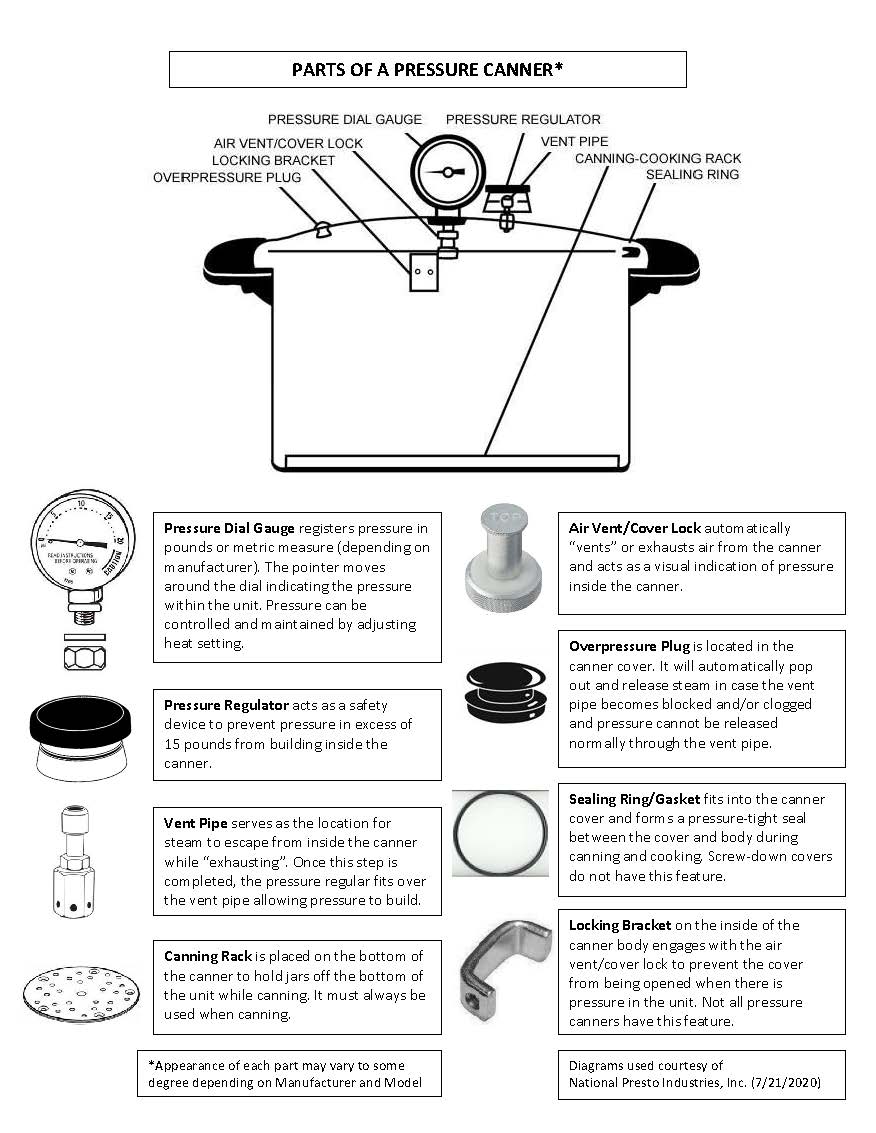

Becoming Familiar with the Parts of a Pressure Canner

(See figure 1 & 2 below)

Older model pressure canners (made before 1970) were heavy-walled kettles with clamp-on or turn-on lids fitted with dial-type gauges. A vent port, either in the form of a petcock that opened for venting and closed to build pressure, or a vent port that was covered with a counterweight after venting. A safety fuse (or plug) was also present. Modern pressure canners are mainly lightweight, thin-walled kettles and most have turn- on lids. They usually have a perforated metal rack or basket with handles, rubber gasket, a dial or

weighted gauge, an automatic vent/cover lock, a vent port (steam vent) to be closed with a counterweight or weighted gauge, and a safety fuse or plug.

Note: When purchasing a used pressure canner, make certain all parts are accounted for and in good condition. It is nearly impossible to find replacement parts for older models.

*Image courtsey of National Presto Industries

Selecting the Correct Processing Time and Pressure

To ensure the safety of food processed in the pressure canner, use processing times listed for scientifically-tested recipes (dated 1988 or later) and adjust for altitude using the chart below. Keep in mind that failing to follow proper processing times and pressure recommendations may result in spoiled food (mold, bacteria, and other microorganisms) and possibly fatal food poisoning.

Pressure Canner and Altitude

The steam-pressure method is used for low-acid foods. Normally, the pressure given for low acid foods in canning guides is for weighted-gauge canners at altitudes at or below 1,000 feet above sea level. At altitudes of 1,001 feet of above, adjust the processing pressure according to the STEAMPRESSURE CANNER chart for the type of steampressure canner being used.

| Altitude (ft) | Pressure Required (lbs) | |||

|---|---|---|---|---|

| Weighted Guage | Dial Guage | |||

| 0-1000 | ||||

| 10 | 11 | |||

| 1001-2000 | ||||

| 15 | 11 | |||

| 2001-4000 | ||||

| 15 | 12 | |||

| 4001-6000 | ||||

| 15 | 13 | |||

| 6001-8000 | ||||

| 15 | 14 | |||

| 8001-10,000 | ||||

| 15 | 15 | |||

Basic Steps in Pressure Canning

-

Center the canner over the burner. When jars of food ready for canning, put the rack and hot water into the canner. If the amount of water is not specified with a given food, use 2 to 3 inches of water. Longer processing times require more water (for example, smoked fish). Always follow the directions with USDA processes for specific foods if they require more water be added to the canner.

For hot packed foods, you can bring the water to 180°F. ahead of time, but be careful not to boil the water or heat it long enough for the depth to decrease. For raw packed foods, the water should only be brought to 140°F.

-

Place filled jars, fitted with new lids, and metal screw bands on the jar rack in the canner, using a jar lifter. When moving jars with a jar lifter, make sure the jar lifter is securely positioned below the neck of the jar (below the screw band of the lid). Keep the jar upright at all times. Tilting the jar could cause food to spill into the sealing area of the lid.

-

Fasten the canner lid securely. Leave the weight off the vent port or open the petcock.

- Turn the heat setting to its highest position. Heat until the water boils and steam flows freely in a funnel-shape from the open vent port or petcock. While maintaining the HIGH heat setting, let the steam flow (exhaust) continuously for 10 minutes.

- After this venting, or exhausting, of the canner, place the counterweight or weighted gauge on the vent port, or close the petcock. The canner will pressurize during the next 3 to 10 minutes.

-

Start timing the process when the pressure reading on the dial gauge indicates that the recommended pressure has been reached, or, for canners without dial gauges, when the weighted gauge begins to jiggle or rock as the manufacturer describes.

-

Regulate the heat under the canner to maintain a steady pressure at, or slightly above, the correct gauge pressure. One type of weighted gauge should jiggle a certain number of times per minute, while another type should rock slowly throughout the process – check the manufacturer's directions.

- Loss of pressure at any time can result in underprocessing, or unsafe food.

- Quick and large pressure variations during processing may cause unnecessary liquid losses from jars.

- IMPORTANT: If at any time pressure goes below the recommended amount, bring the canner back to pressure and begin the timing of the process over, from the beginning (using the total original process time). This is important for the safety of the food.

-

When the timed process is completed, turn off the heat, remove the canner from the heat (electric burner) if possible, and let the canner cool down naturally. (It is okay to leave the canner in place after you have turned off the gas burner.) While it is cooling, it is also depressurizing. Do not force cool the canner. Forced cooling may result in food spoilage. Cooling the canner with cold running water or opening the vent port before the canner is fully depressurized are types of forced cooling. They will also cause loss of liquid from jars and seal failures. Force cooling may also warp the canner lid.

Even after a dial gauge canner has cooled until the dial reads zero pounds pressure, be cautious in removing the weight from the vent port. Tilt the weight slightly to make sure no steam escapes before pulling it all the way off. Newer canners will also have a cover lock in the lid or handle that must release after cooling before the lids are twisted off. Do not force the lid open if the cover locks are not released. Manufacturers will provide more detailed instructions for particular models.

- Depressurization of older canner models without dial gauges should be timed. Standard size heavy-walled canners require about 30 minutes when loaded with pints and 45 minutes when loaded with quarts. Newer thin-walled canners cool more rapidly and are equipped with vent locks that are designed to open when the pressure is gone. These canners are depressurized when the piston in the vent lock drops to a normal position. Some of these locks are hidden in handles and cannot be seen; however, the lid will not turn open until the lock is released.

-

After the canner is completely depressurized, remove the weight from the vent port or open the petcock. Wait 10 minutes; then unfasten the lid and remove it carefully. Lift the lid with the underside away from you so that the steam coming out of the canner does not burn your face.

-

Using a jar lifter, remove the jars one at a time, being careful not to tilt the jars. Carefully place them directly onto a towel or cake cooling rack, leaving at least one inch of space between the jars during cooling. Avoid placing the jars on a cold surface or in a cold draft.

-

Let the jars sit undisturbed while they cool, from 12 to 24 hours. Do not tighten ring bands on the lids or push down on the center of the flat metal lid until the jar is completely cooled.

-

Remove screw bands from sealed jars. Ring bands can be washed and dried and put away for using another time. Put any unsealed jars in the refrigerator and use first.

-

Wash jars and lids to remove all residues.

-

Label jars and store in a cool, dry place out of direct light.

-

Dry the canner, lid and gasket. Take off removable petcocks and safety valves; wash and dry thoroughly.

Additional Safety/Operating Tips

Gauges: Check dial gauges for accuracy before use each year and replace if they read high or low by more than 2 pounds pressure. Gauges may be checked at most county Cooperative Extension offices. Replacement gauges and other parts for canners are often available at stores offering canning equipment or from canner manufacturers. When ordering parts, it will be helpful to know the model number of your canner.

Many modern dial-type canners also have vent ports with counter weights that can register 5, 10, and 15 lbs. pressure. Those who prefer to “listen” to pressure readings can use the rocking sound of the 15 lbs. weight instead of having to check the needle on the dial-type gauge for accuracy.

Gaskets: Handle canner lid gaskets carefully and clean them according to the manufacturer’s directions. Nicked or dried gaskets will allow steam leaks during pressurization of canners and should be replaced. Keep gaskets clean between uses. A lid which is difficult to remove after cooling may indicate a gummy, or dry gasket and is reason to replace it.

Source

- USDA Complete Guide to Home Canning and Preserving, 2009 Revision. Also available online: http://extension.usu.edu/foodsafety/htm/publica tions/publication=15640

Authors

Kathleen Riggs, Brian Nummer

Related Research