043 - Producing Maple Syrup From Boxelder and Norway Maple Trees

Jesse Mathews, Youping Sun, Kelly Kopp, Darren McAvoy, Steven Price, Paul Harris, Michael Farrell, Michelle Sagers, and Patrick Kelly

Introduction

When you think of maple syrup, you probably think of Canada since over 75% of the world's supply is produced there (Crops, 2021). In high maple syrup-producing areas like Canada, sugar maples (Acer saccharum) are the most popular trees to tap for maple syrup due to the higher sugar content in their sap (Perkins, 1996). However, sap can be harvested from any maple species, as well as other tree species such as birch and walnut. In Utah, two common tappable maple species are boxelder, sometimes called ashleaf maple (Acer negundo), and Norway maple (Acer platanoides). Both species are abundant throughout the state, with the former primarily found in natural mid-elevation canyons and the latter extensively planted in urban landscapes.

Maple syrup is a natural source of sugar and can be used in many recipes to make yummy treats and foods. The best part is that it is relatively easy to obtain and simple to make. The required components to produce maple syrup include: (1) correct-sized trees in the Acer genus, (2) the right temperatures for sap flow, and (3) the equipment to collect and process sap.

Tree Identification

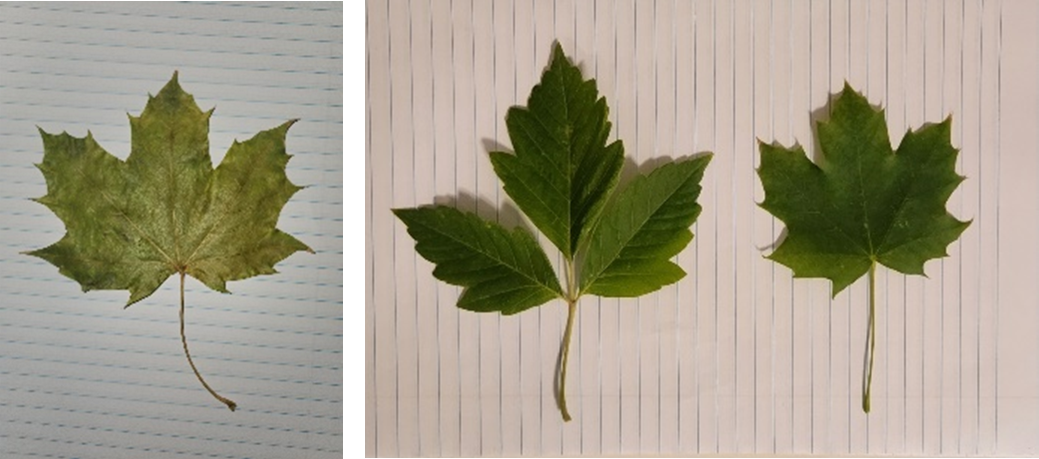

Maple trees are often identified by their unique leaf shape, but this can lead to misidentification. For example, London planetree (Platanus x acerifolia) leaves have a classic maple leaf shape and a similar growth habit to Norway maple (Figure 1). Boxelder is a maple, but its leaves do not resemble typical maple leaves as they have three leaflets. Another helpful identification characteristic is the fruits. Maple fruits are called samaras, come in attached pairs, and have “wings” adjacent to one side of the seed (Figure 2). Ash trees, which are commonly misidentified as maples, also have samaras, but they are singular with one seed and one wing.

Figure 1. Comparison: (left) London Planetree; (middle) Boxelder; (right) Norway Maple

Figure 2. Samara Comparison: (left) Boxelder; (right) Norway Maple

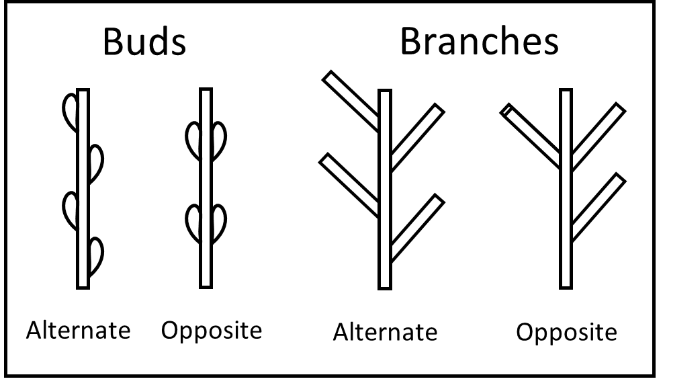

Maples have opposite buds (Figure 3), which means that buds, stems, and leaves are arranged directly across from one another rather than staggered. This pattern can greatly help narrow down the possibilities during the dormant season, as the only other common trees in Utah landscapes with this arrangement are ash, horse chestnut, and dogwood. Ashes are easy to misidentify as maple because of this shared characteristic. Ash buds typically have more pronounced “knobs” at each bud where the leaf was attached. Maple buds have a smoother appearance without noticeable scars where the leaf was attached (Figure 4). Alternative branching, where the buds, leaves, and stems are staggered, is more common than opposite branching. Figure 3. Budding and Branching Comparison

Figure 3. Budding and Branching Comparison

There are a few important things to consider when picking a tree to tap. The first one is the diameter at breast height (DBH), which is the tree’s diameter around 4.5 feet from the ground. The general rule is a minimum of 10 inches of trunk DBH for tapping. Trees with a DBH less than 10 inches can be tapped but will produce less sap.

A concern with tapping smaller trees is that it will harm the tree; however, they can be sustainably tapped for many years if done right. This calculator found at https://mapleresearch.org/pub/tzspreadsheet/ from the University of Vermont is a good resource to aid in tapping sustainably. Larger trees over 18 inches in DBH can support more than one tap without harming the tree or sacrificing flow rate (Table 1; Carusone, 2020).

Table 1. Recommended Number of Taps Per Trunk Diameter

|

Another thing to consider when selecting a tree to tap is finding healthy trees, which is especially important when using smaller-diameter trees. Tap holes in unhealthy trees can take longer to heal, allowing for more opportunity for disease and insects to invade the tree (Wolfe, 2019). It can also affect sap production and sugar content. Use healthy-looking trees with big crowns and little to no dead branches. Make sure the trees are on land you own or you have permission from the owners to tap the trees. Trees on public lands can often be tapped, but permits will usually need to be obtained from the local management office.

Temperature

The driving force behind sap flow is temperature. Alternating temperatures below freezing at night followed by daily temperatures above freezing during the day cause the sap to flow. Freezing temperatures cause sap to flow up into the branches. Warmer temperatures cause this water to fall back down the tree and pick up the sugars, which seep from the sapwood when it warms up (Tyree, 1984). This pattern occurs throughout the dormant season until nighttime temperatures stay above freezing in the springtime. Tracking local weather data can identify when this occurs in your area, but in Logan, Utah, these temperatures generally start occurring mid to late February. The Utah Climate Center is a good place to check for local temperatures.

Once the tree’s buds start to swell, the sap will change in chemistry, imparting an off-flavored “buddy” syrup that most people dislike. When your syrup starts to taste “buddy,” you should pull your spouts and let the trees begin the healing process over the taphole.

Tapping a Tree

To start tapping, choose a spot on the tree about breast height. The ideal height is wherever it is comfortable to drill and collect sap that will not be buried by snow nor too high to reach when the snow melts. The hole should be about 1.5 inches deep and the same diameter as the spile, which is the hollow “spigot” put into the tree. Place the drill bit and spile next to one another and mark the bit where the spile ends to help gauge the right depth. A snug fit of the spile into the tree is required; drill straight, using the bit to clear out shavings and produce a clean hole. Gently tap the spile into the hole until it has a snug fit and you hear the sound change when gently tapping on the spout.

Although south-facing tapholes often produce more sap at the beginning of the season, north-facing tapholes will tend to produce more sap toward the season’s end. Overall, it does not matter which side of the tree is tapped. The most important thing is to move your taps around the tree when you drill a hole every year so that they always go into fresh white sapwood.

Hang a bucket or other receptacle to collect the sap (Figure 5). Everything from milk jugs to bathtubs have been used to collect sap, but buckets are the most common. A good collection receptacle will be clean, food-grade, and easy to secure so it cannot be easily knocked off by wind or other factors. A covering is optional but highly advantageous to help keep the sap clean from foreign objects and reduce the need for straining before processing.

Figure 5. Bucket and Spile

Using the Sap

Sap can spoil if not processed or correctly stored in sufficient time after flowing (Roberge, 2013). Ideally, sap should be processed or stored within a few days of exposure. When sap flow is high, collection may need to occur every day. Sap turns cloudy and will not taste very good once it spoils (Kidd, 2012). If this happens, discard the sap as it is useless. Sap can be stored by freezing for long periods (Ingham, 2021). Unprocessed sap has been used as a healthy drink called “maple water.” It can also be used as a substitute for water when cooking to add a subtle amount of sugar and various minerals to your dishes (FoodData Central, 2022).

The most popular use for sap is making maple syrup. The ideal syrup has a sugar content between 66%–68%, which involves boiling a significant amount of water out of the sap (Davenport, 2013). Generally, it takes about 40 gallons of sap to make 1 gallon of syrup, so the process takes significant time and energy. The process is as follows:

- Sap should be boiled in a broad, shallow pan of food-grade quality at a depth of 1–1.5 inches for the greatest efficiency in removing the bulk of the water (Figure 6). For hobbyists, this is typically done outdoors over a fire or propane stove. As the water evaporates, add more sap to keep the liquid level within the target depth. This can take significant time, but it should be watched carefully as a low pan may scorch the sugars and ruin the batch.

- Once most of the water evaporates, the syrup should be finished in a more controlled environment such as a kitchen stove where temperatures can be controlled more easily. Once the liquid is golden brown and approaching 217 °F to 219 °F, it should be fine-filtered to remove “sugar sand,” a natural debris from minerals in the sap. Use a cheesecloth or other straining fabric over a colander. It can then be transferred to a smaller pan to finish reducing indoors.

- The syrup is done when it reaches a temperature of 7 °F above the boiling point of water. Note that this changes daily based on the barometric pressure and elevation at which you are boiling. A hydrometer or refractometer can be used to measure the syrup until 66 Brix is achieved. If the syrup is boiled too little, it will be thin and prone to spoilage due to excess water. If the syrup is boiled too long, it may crystallize.

- Syrup can be canned or bottled for long-term storage or frozen indefinitely. To bottle, heat syrup to 179 °F to 190 °F and immediately transfer to sterilized jars. Add lids and tighten rings until finger tight and allow to cool. If properly packaged, it will last for many years unopened, but once it has been opened, it should be refrigerated. Use caution when using old syrup and watch for off-colors and off-tastes as a sign of spoilage (Stokes Nature Center, 2020). If not canning or bottling the syrup, store it in bottles in the refrigerator while it is being consumed (Figure 7).

Figure 6. Boiling Preconcentrated Sap Into Syrup at Home

Figure 7. Homemade Utah Maple Syrup, Ready for the Refrigerator

Syrup can be used as a traditional condiment or an ingredient in many other tasty foods. Some of these include maple taffy, fudge, pie, pudding, baked beans, and more. It can also be used as a sugar substitute, adding a natural maple flavor to other goods. Due to its low glycemic index, it is considered a healthier sugar (Higdon et al., 2016). A ratio of 0.75:1 syrup to white sugar is recommended when used as a substitute. For every 1/3 cup of syrup used, reduce the required water by 1 tablespoon (Hillsboro Sugarworks, 2022). There are countless recipes online that use maple syrup; be creative, and you may just find a new favorite use for your “liquid gold.”

Figure 8. Old Tapping Holes: (left) 8 Months After Tapping; (right) 2 Years After Tapping

Tapping the Next Year

If kept healthy otherwise, a maple tree can be tapped for the duration of its life. Some speculate that in Vermont, trees currently being tapped were alive during the Civil War (Hillsboro Sugarworks, 2022). Creating a hole in the tree to collect sap does not cause significant long-term damage to a healthy tree (Figure 8). Within a few months, it will scar over and will not cause any further distress to the tree.

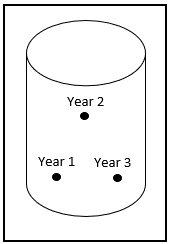

That being said, it is important to drill next year’s hole in a different location since sap does not flow through scar tissue. A general rule is to move laterally of the previous year’s tapping location at least 1 inch and vertically about 8–12 inches (Figure 9). Moving the taps in this zig-zag pattern ensures that the tree has time to add more sapwood to the original tapping location before the same spot is tapped again.

Figure 9. Tapping Pattern for Multiple Years

References

Carusone, D. (2020). Maple syrup production. Cornell Cooperative Extension. https://warren.cce.cornell.edu/home-page/natural-resources/maple-syrup-production

Crops and Horticulture and Division, Agriculture and Agri-Food Canada. (2021). Statistical overview of the Canadian maple industry 2021. Government of Canada.

Davenport, A. L. (2013). Maple syrup production for the beginner. Penn State Extension.

FoodData Central. (2022). Syrups, maple. USDA Agricultural Research Service.

Higdon, J., Drake, V., Delage, B., & Liu, S. (2016). Glycemic index and glycemic load. Oregon State University Linus Pauling Institute.

Hillsboro Sugarworks. (2022). Frequently asked questions. https://hillsborosugarworks.com/pages/faqs

Ingham, B. H. (2021). Unsafe to can tree sap at home. University of Wisconsin-Madison Extension. https://winnebago.extension.wisc.edu/2021/04/13/unsafe-to-can-tree-sap-at-home/

Kidd, R. (2012). Making maple syrup in your backyard: Part 2. Michigan State University Extension.

Perkins, T. D., Heiligmann, R. B., Koelling, M. R., & van den Berg, A. K. (2022). North American maple syrup producers manual (3rd ed., pp. 3-1–3-11). University of Vermont and The North American Maple Syrup Council.

Roberge, S. (2013). Maple sugaring: Tips for beginners and backyard maple sugar producers. University of New Hampshire Cooperative Extension.

Stokes Nature Center. (2020). Maple tapping [Workshop handout].

Thériault, M., Caillet, S., Kermasha, S., & Lacroix, M. (2006). Antioxidant, antiradical and antimutagenic activities of phenolic compounds present in maple products. Food Chemistry, 98(3), 490–501.

Tyree, M. (1984). Maple sap exudation: How it happens. Maple Syrup Journal, 4(1), 10–11.

Wolfe, L. M. (2019). Maple: A sap to syrup guide, A manual for career and technical centers of Vermont [Master’s project, University of Vermont, pp. 25–26]. Rubenstein School Masters Project Publications, 21. https://scholarworks.uvm.edu/rsmpp/21/

Disclaimer and Acknowledgments

All photos, graphs, and tables may not be used without written permission from the authors. Pictures by Jesse Mathews and Youping Sun. This project was funded in part by the United State Department of Agriculture (USDA) Agricultural Marketing Service Acer Access and Development Program, Utah State University (USU) Extension Grants Program, Utah Agricultural Experiment Station (UAES), and the USU’s Center for Water-Efficient Landscaping (CWEL). The information reflects the views of the author(s) and not granting agencies. We sincerely thank Utah Farm Bureau Federation, the Stokes Nature Center, Logan, UT; Providence City, UT; Smithfield City, UT; and USU’s Landscape Operations and Maintenance.

In its programs and activities, including in admissions and employment, Utah State University does not discriminate or tolerate discrimination, including harassment, based on race, color, religion, sex, national origin, age, genetic information, sexual orientation, gender identity or expression, disability, status as a protected veteran, or any other status protected by University policy, Title IX, or any other federal, state, or local law. Utah State University is an equal opportunity employer and does not discriminate or tolerate discrimination including harassment in employment including in hiring, promotion, transfer, or termination based on race, color, religion, sex, national origin, age, genetic information, sexual orientation, gender identity or expression, disability, status as a protected veteran, or any other status protected by University policy or any other federal, state, or local law. Utah State University does not discriminate in its housing offerings and will treat all persons fairly and equally without regard to race, color, religion, sex, familial status, disability, national origin, source of income, sexual orientation, or gender identity. Additionally, the University endeavors to provide reasonable accommodations when necessary and to ensure equal access to qualified persons with disabilities. The following individuals have been designated to handle inquiries regarding the application of Title IX and its implementing regulations and/or USU’s non-discrimination policies: Executive Director of the Office of Equity, Matt Pinner, JD, matthew.pinner@usu.edu, Title IX Coordinator, Hilary Renshaw, hilary.renshaw@usu.edu, Old Main Rm. 161, 435-797-1266. For further information regarding non-discrimination, please visit equity.usu.edu, or contact: U.S. Department of Education, Office of Assistant Secretary for Civil Rights, 800-421-3481, ocr@ed.gov or U.S. Department of Education, Denver Regional Office, 303-844-5695 ocr.denver@ed.gov. Issued in furtherance of Cooperative Extension work, acts of May 8 and June 30, 1914, in cooperation with the U.S. Department of Agriculture, Kenneth L. White, Vice President for Extension and Agriculture, Utah State University.

Published April 2023