034 - Biochar for Forest Restoration in Western States

Introduction

Figure 1. Chipped (masticated) juniper. Photo courtesy of Patrick Rappold.

Forest restoration projects in the western United States, including thinning for hazardous fuel reduction, leave behind a significant amount of wood waste or biomass, which include small-diameter logs, tree tops, and branches, as well as needles, leaves, and sometimes roots. These materials, also called forest residue or slash, are usually gathered into large piles and burned or left to decompose (Sue et al. 2016). This biomass almost always goes unused due to the wide price gap between high harvesting and transportation costs and low market values. However, a product called biochar is giving new hope for forest restoration in the West.

If forest restoration projects could produce marketable materials, then the projects would be more affordable and more restoration could get done. Biochar is one of those materials. Pinyon-juniper (PJ) woodlands, for example, occupy about 47 million acres in the western United States (Evans 1988, Chambers et al. 1999). In many places PJ has expanded into areas formerly dominated by sagebrush and other important rangelands, which can negatively impact wildlife habitat, increase erosion, cause loss of herbaceous species, and increase fire hazard and severity. Because of biochar’s various potential uses, its production may offer a way to make the restoration of these ecosystems economically feasible. This fact sheet provides an overview of what biochar is, how it is produced, and how it can be used in land reclamation and for other purposes.

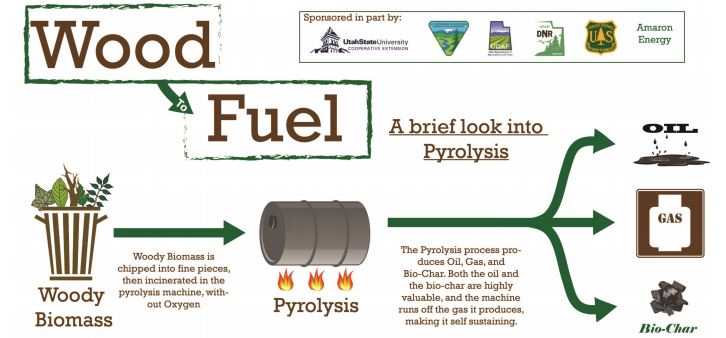

Figure 2. Production of bio-oil, bio gas and biochar by pyrolysis. Graphic courtesy of Darren McAvoy.

Figure 2. Production of bio-oil, bio gas and biochar by pyrolysis. Graphic courtesy of Darren McAvoy.

What is Biochar and How is It Produced?

Biochar is made from biomass via pyrolysis, a thermochemical conversion of organic material under conditions of limited oxygen and controlled high temperatures. Pyrolysis can be classified into four modes based on operating conditions and the desired products. Table 1 summarizes the main pyrolysis techniques based on temperature, heating rate, and major products. Pyrolysis produces mainly biochar when conducted at a temperature of less than 400°C with a long residence time (time that the material is exposed to heat), while bio-oil is the main product when the system is conducted at an intermediate temperature of around 500°C with a short residence time (Bridgewater 2006).

Figure 3. Five pyrolysis products plus pulp chips. Clockwise from top left: microchips from mixed conifer woody biomass, 3-inch pulp chips for reference (center), high carbon biochar resulting from pyrolysis at 1,000oC, pellets made from char, high surface area activated carbon made from char (biochar), and pellets made from wood. Photo courtesy of Nate Anderson, USDA Forest Service.

Operationally, woody biomass that is going to be used for conversion to biochar and other products is typically pre-processed, usually by chipping or mastication (Figure 1) and screened to a uniform small chip size. The moisture content of the chips is also reduced, ideally to ≤ 10%. Moist wood can also be processed but this slows production. Once dry chips have been produced they are fed into a high-temperature pyrolysis reactor. During pyrolysis (Figure 2) the biomass is heated, which evaporates any remaining moisture. Further heat input breaks down the major biomass components (cellulose, hemicellulose, and lignin) into pyrolytic vapors. The pyrolytic vapors consist of incondensable gases such H2, CO, and CO2 (known as light hydrocarbons), and condensable vapors which can be formed into a liquid. We call this mixture of liquid organic compounds bio-oil (Neves et al. 2011).

Thus, pyrolysis breaks down the organic portion of the biomass into three products (Figures 3 & 4), a carbon-rich solid (biochar), a liquid (bio-oil), and a synthesis gas (syngas) (Sensoz et al. 2000, Babu 2008, Briens et al. 2008, Vamvuka 2011).

Biochar, therefore, is a refined charcoal (sometimes called bio-coal) left behind after pyrolysis. Bio-oil is similar to crude oil and can be refined to make heating oil or a variety of other biochemical products. Bio-oil can be further refined to create very high value products such as adhesives and plastics that have the potential to produce significant revenues. The syngas is similar to propane and can be used to dry the biomass or to operate the machinery, so the process can be selfsustaining to a large extent.

Figure 4. Biochar pellets (left) produced using hightemperature pyrolysis compared to pellets made from torrified wood (right). Photo courtesy of Nate Anderson, USDA Forest Service.

Numerous laboratory and pilot-scale studies of pyrolysis and gasification of woody biomass to produce biochar and other products have been done (Mohan et al. 2006, Kumar et al. 2009, Van der Stelt et al. 2011) and several systems are available commercially. For example, the Tucker Renewable Natural Gas System (Tucker RNG System) is a core conversion technology that produces a methane-rich syngas and a high carbon char output from a wide range of woody biomass feedstocks (Figure 5).

However, the associated support systems (e.g. feedstock storage, handling and drying, gas scrubbers, gas compression and storage, and fuel storage) makes it impractical to be used for most restoration projects. They are very costly to tear down and reassemble at a field site. The Tucker RNG System also requires high temperatures (1,000°C) and they are not designed for a daily warm up, cool down cycle, but rather for continuous operation.

Several companies, such as Western Renewable Technologies in Linden, Utah, are developing and marketing commercial equipment for biomass conversion that can be deployed near the biomass source to avoid long haul transportation and associated costs of bulky woody biomass. Amaron Energy, a Utah-based company, has developed a mobile (field deployable) pyrolysis reactor capable of producing varying levels of biochar, biogas, and bio-oil (Figure 6). Amaron is currently working with PacifiCorp on using torrified wood pellets, which release fewer volatile organic compounds and heavy metals than coal, as partial replacement for coal in its coal-fired power plants.

| Mode | Conditions | Liquid (%) | Solid or char (%) | Gas (%) |

|---|---|---|---|---|

| Fast | RT (500oC) Very high HR (> 1000oC/sec) Short hot vapor residence time ~ 1 sec | 75 | 12 | 13 |

| Intermediate | RT (400-500oC) HR range (1-1000oC /sec) Hot vapor residence time ~10-30 sec | 50 | 25 | 25 |

| Slow-Torrifaction | RT (~290 oC) HR (1oC /sec) Solids residence time (~30 min) | 0-5 | 77 | 23 |

| Slow-Carbonization | Low temperature (~400-500oC) HR (1oC /sec) Very long residence time (days) | 30 | 35 | 35 |

Table 1. Modes of pyrolysis and major products (RT = reactor temperature, HR = heating rate; adapted from Bridgewater, 2006)

What Are the Uses for Biochar?

Figure 5. The Tucker RNG thermal conversion system uses forest biomass and other woody material as its fuel source. Photo courtesy of Nate Anderson, USDA Forest Service.

Biochar has a number of unique chemical and physical properties that make it very useful and potentially valuable. Its most important property is its ability to absorb elements and hold them, especially in the soil. Karhua et al. (2011) Uzoma, et al. (2011) Absorbing and holding water and nutrients makes them more available to plants. Biochar is a fairly stable source of carbon when it is incorporated in the soil as well. It breaks down slowly so that humic acid and soil nitrogen is available to plant roots over time. Absorbing and holding hazardous or toxic elements can keep them from translocating through soil and into groundwater and can give microbes time and a favorable environment to them break down.

Biochar’s various properties give it a potential economic value if markets can be developed for it. This can make forest restoration projects financially viable by providing a valuable product made from woody biomass (Anderson et al. 2013). Its economic value can enhance rural economic development, and can make renewable energy generation possible, enhancing national energy security (Groot et al. 2016). Moller (2013), Page-Dumroese (2013), Anderson et al. (2013), and Chalker-Scott (2014) identify six primary markets or uses for biochar that include (1) large-scale agriculture, (2) forest and rangeland management (e.g. through post-fire vegetation responses), (3) mine reclamation, (4) urban forests and golf courses, (5) horticulture, forest nursery, gardening, and vegetable production, and (6) industrial applications (e.g. activated carbon).

Figure 6. The Amaron Energy Rotary Pyrolysis Reactor in a field setting. Photo courtesy of Darren McAvoy

Figure 7. USU Extension crew applying biochar at a commercial organic vegetable farm near Kaysville, Utah. Photo courtesy of Darren McAvoy.

The Utah Biomass Resources Group currently is conducting field trials of biochar as a soil amendment under both agricultural and reclamation conditions. One study is amending the soil of several production vegetable farms located along the Wasatch Front near Salt Lake City, Utah. It seeks to determine the relative productivity of these amended soils to enhance tomato and melon growth and to protect against the common root disease phytophthora (Figure 7). Final results for this study are not yet complete but appear to be promising.

Another study being conducted in the Uinta Basin near Vernal, Utah looks at using biochar as a soil amendment on an abandoned oil/gas drilling pad now overrun with noxious weeds. Reclamation of the site using standard techniques had failed. Soil moisture, plant growth and a variety of other parameters are being monitored to examine the effects of a variety of biochars and application rates The project goals include reducing cost and length of time for contractors to achieve bond release, increase seedling establishment success, especially for native plant species, improve soil growing conditions, and others. See complete details on this ongoing study.

Conclusions

Biochar has value both as a forest product and as an amendment for restoration projects in the West. The main barrier to biochar gaining more market share, in the soil amendment market, is capacity limitations of current biochar production technologies. Research to identify processing techniques that will increase biochar yield from woody biomass is ongoing. Biochar manufacture for fuels reduction provides a potential avenue toward a marketbased solution for implementing forest and grassland restoration projects in the western United States. Implementing new technologies, such as biochar production, can shrink the gap between harvesting/transportation costs and true market value. Further developing this industry is a key part of the restorationeconomics puzzle. For landowners and agencies in western states seeking market based solutions for implementing grassland restoration projects and hazardous fuels reduction projects, biochar is a promising product. Numerous research studies illustrate the ability of biochar to increase water retention in arid soils and increase plant productivity. While there are several methods of producing biochar, the underlying catalyst is exposure of woody biomass to either high heat for short time intervals or moderate heat levels over a sustained time period. Research to identify processing techniques that will increase biochar yield from woody biomass is ongoing at public and private laboratories. The drivers for the research initiatives is to conserve water and forest resources in the face of uncertain climatic changes.

Key Terms

- Pyrolysis – a process of heating organic materials (e.g. woody biomass) in the absence of oxygen to yield a series of bioproducts, bio-char, bio-oil, and syngas.

- Biochar – a refined charcoal (sometimes called bio -coal) left behind after heating biomass in a closed system under limited supply of oxygen.

- Bio-oil – generally considered a crude oil (sometimes called liquid pyrolysis oil) and can be furthered refined to create heating oil or a variety of other biochemical products

- Synthesis gas – similar to propane (sometimes called syngas) and can be used to dry the biomass or to heat the pyrolysis unit for continued production.

- Torrified wood – a densified wood product that is cooked at lower temperatures than biochar

Resources

- Anderson, N., D. Page-Dumroese, J.G. Jones, D. McCollum, S. Baker, D. Loeffler, and W. Chung. 2013. A comparison of producer gas, biochar, and activated carbon from two distributed-scale thermochemical conversion systems used to process forest biomass. Energies 6:164–183.

- Babu, B.V. 2008. Biomass pyrolysis: A state-of-the-art review. Biofuels Bioprod. Biorefining 2:393–414.

- Bridgewater, T. 2006. Biomass for energy. J. Sci. Food Agric. 86:1755–1768. Briens, C., J. Piskorz, and F. Berruti. 2008. Biomass valorization for fuel and chemicals production: A review. Int. J. Chem. React. Eng. 6.1-46.

- Chalker-Scott, L. 2014. Biochar: A home gardener’s primer. Washington State University, Puyallup Research and Extension Center. Washington State University Extension and U.S. Department of Agriculture. 4 pp.

- Chambers, J.C., S.B. Vander Wall, and E.W. Schupp. 1999. Seed and seedling ecology of pinyon and juniper species in the pygmy woodlands of Western North America. Bot. Rev. 65:1–38.

- Groot H, Fernholz, K., Howe, F.M.,Bowyer, J., and Ratkovich, S. 2016. Biochar 101: An introduction to an ancient product offering modern opportunities. Dovetail Partners. P 13.

- Evans, R.A., 1988. Management of pinyon-juniper woodlands. USDA For. Serv. Rep. INT-249 Ogden UT.

- Karhua, K., T Mattila, T., Bergströma, I., Reginac, K., 2011. Biochar addition to agricultural soil increased CH4 uptake and water holding capacity – Results from a short-term pilot field study. Agriculture, Ecosystems and Environment 140, 309-313.

- Kumar, A. Jones, D. Hanna, M. 2009. Thermochemical biomass gasification: A review of the current status of the technology. Energies, 2, 556– 581.

- Miller, S., Essen, M., Anderson, N., Page-Dumroese, D., McCollum, D., Bergman, R., Elder, T. 2014. Burgeoning biomass: Creating efficient and sustainable forest biomass supply chains in the Rockies. Science You Can Use Bulletin, Issue 13. Fort Collins, CO: Rocky Mountain Research Station, p 10.

- Mohan, D., Pittman, C.U., Steele, P.H., 2006. Pyrolysis of wood/biomass for bio-oil: a critical review. Energy Fuels 20, 848–889. Moller, E. D. 2013. Biochar – A Soil Restorative – Useful in Agriculture and Forestry. University of Nevada, Reno: Reno, NV.

- Neves, D., Thunman, H., Matos, A., Tarelho, L., Gomez-Barea, A., 2011. Characterization and prediction of biomass pyrolysis products. Prog. Energy Combust. Sci. 37, 611–630.

- Page-Dumroese, D. 2013. Summary of Biochar Studies. USDA Forest Service, Rocky Mountain Research Station: Moscow, ID.

- Sensoz, S., Angin, D., Yorgun, S., 2000. Biooil production from an oilseed crop: fixed-bed pyrolysis of rapeseed (Brassica napus L.). Energy Sources 22, 891–899.

- Tausch, R. 2011. Power Point - Society for Range Management rangelands.org/deserts/powerpoints. Rocky Mountain. Research Station, Reno. NV.

- Uzoma, K., Inoue, M., Andry, H., Zahoor, A., Nishihara, E., 2011. Influence of biochar application on sandy soil hydraulic properties and nutrient retention. Journal of Food, Agriculture & Environment 9. 1137-1143.

- Vamvuka, D., 2011. Bio-oil, solid and gaseous biofuels from biomass pyrolysis processes- An overview. Int. J. Energy Res. 35, 835–862.

- Van der Stelt, M.J.C.; Gerhauser, H.; Kiel, J.H.A.; Ptasinski, K.J. 2011. Biomass upgrading by torrefaction for the production of biofuels. Biomass and Bioenergy, 35(9), 3748-3762.

Published May 2017.