Irrigation Management In High Tunnels

Introduction

High tunnels provide season extension for various high-value horticulture crops in a diverse range of climates. These large, plastic-covered structures modify the environmental conditions of the covered area. Temperature management is commonly the focus when growing in high tunnels as this may be the key factor limiting plant growth during much of the year.

While high tunnel temperature management is important, growers also need to address water management to ensure plants are not water-stressed. Common mistakes are underestimating water needs, which stresses plants or creates conditions favoring plant diseases and nutrient leaching from overwatering. The key to good tunnel management is to understand how tunnel temperature impacts water use and how the water requirements of the crop respond to tunnel conditions. With a consistent moisture supply throughout all plant growth stages, growth improves, and fewer negative effects on productivity occur. Knowing when to irrigate and how much water to apply will ensure the high tunnel is properly managed for high productivity. This fact sheet discusses how to best manage irrigation for a range of seasonal growing conditions

Water and Plant Growth

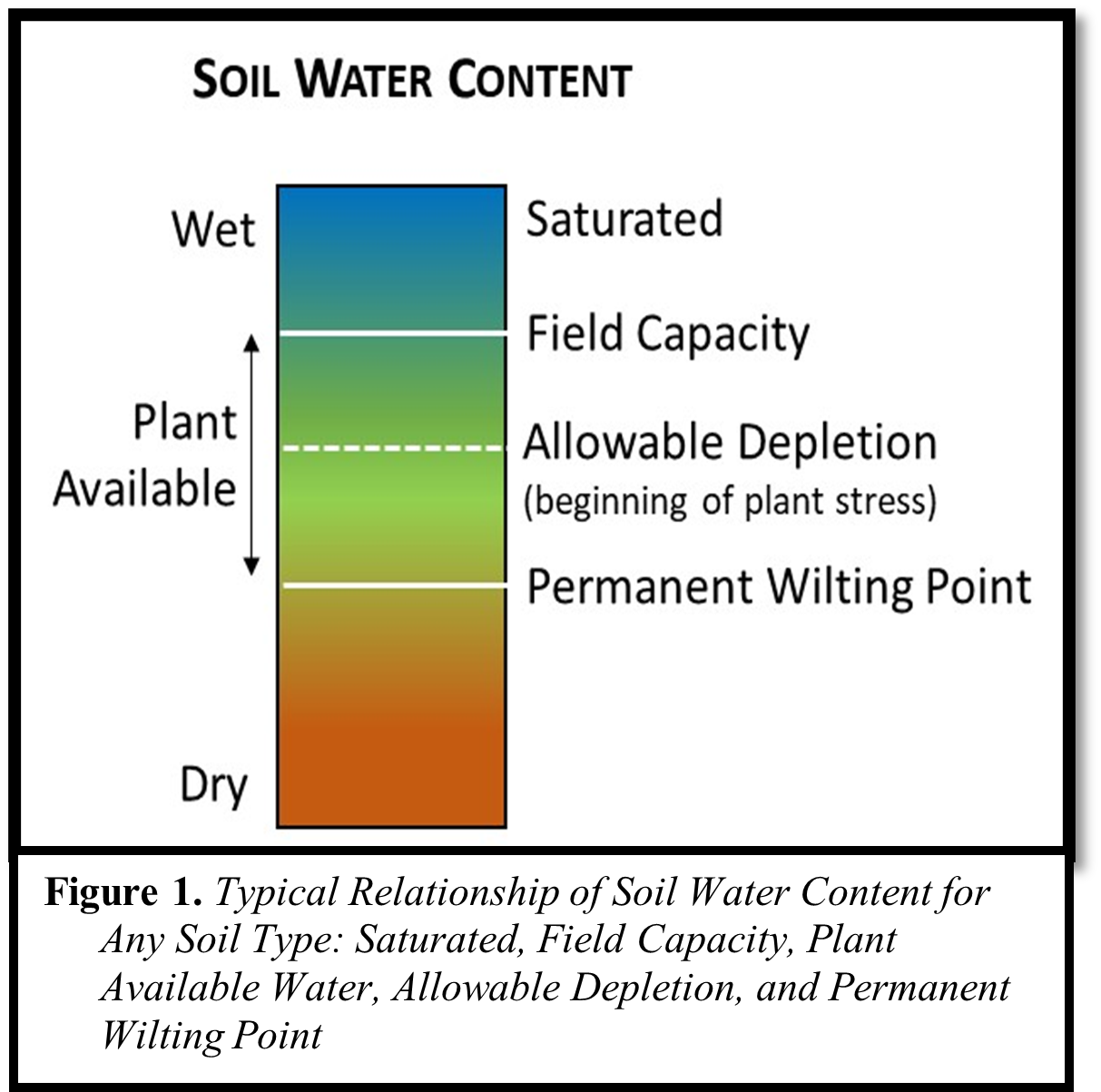

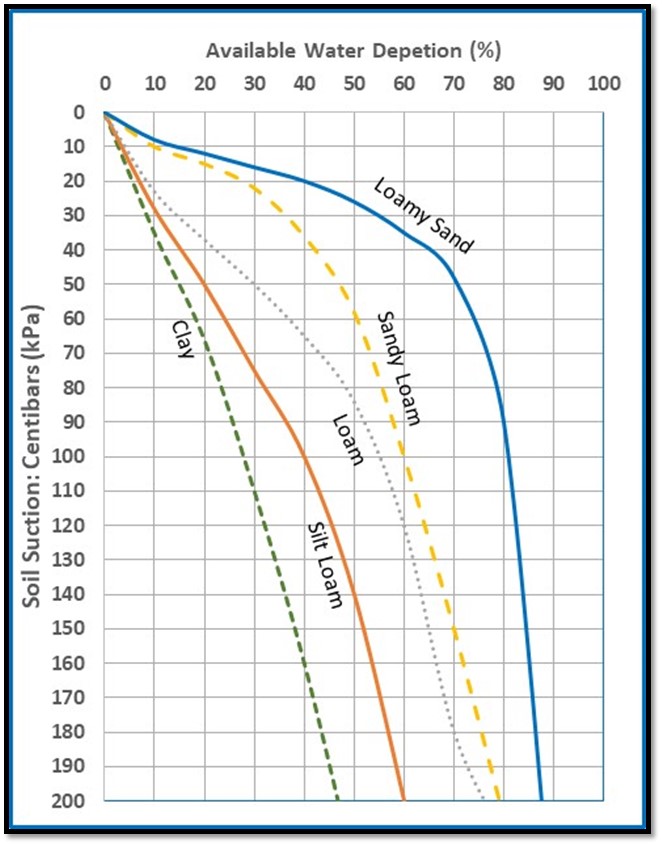

Figure 1 illustrates how soil water content changes from wet to dry conditions. When water is added to soils from irrigation or precipitation, the soil exceeds field capacity. After 1–2 days of draining due to gravity, the soil reaches field capacity. If no additional water is added to the soil, the soil eventually reaches the permanent wilting point, where the amount of available water is less than a plant can extract. Plant available water is the amount of water in the soil between field capacity and permanent wilting point (Figure 1). While plant available water is useful to know, it is more important to know and understand the amount of allowable depletion so plants do not become water-stressed. Depending on soil type, the allowable depletion (easily or readily available water) is the point where plants begin to experience some stress as the roots find it harder to extract water from the soil. Plants vary in how they respond to soil water depletion and where the point of stress begins. The primary goal of soil water management is to maintain soil moisture between field capacity and the crop’s allowable depletion level. By doing this, water is readily available, and plants do not experience water stress. The amount of readily available water is related to the effective rooting depth of the plant and the water holding capacity of the soil.

Water Management

Water use by plants in a high tunnel is often different from that of plants grown in the field. Thus, plant water

use and irrigation inputs are quite different. Most high tunnel growers understand that sunlight warms the plants and soil that then warms the air within the tunnel. Temperatures change rapidly on sunny days, even when outside air temperatures are relatively cold. It is common to ventilate tunnels on sunny days in early spring or even in the late fall to prevent temperatures inside the tunnel from exceeding the crop’s temperature optimum. Just as the temperature is carefully monitored, so too, the soil moisture content in the tunnel needs to be tracked to maintain optimum plant growth conditions.

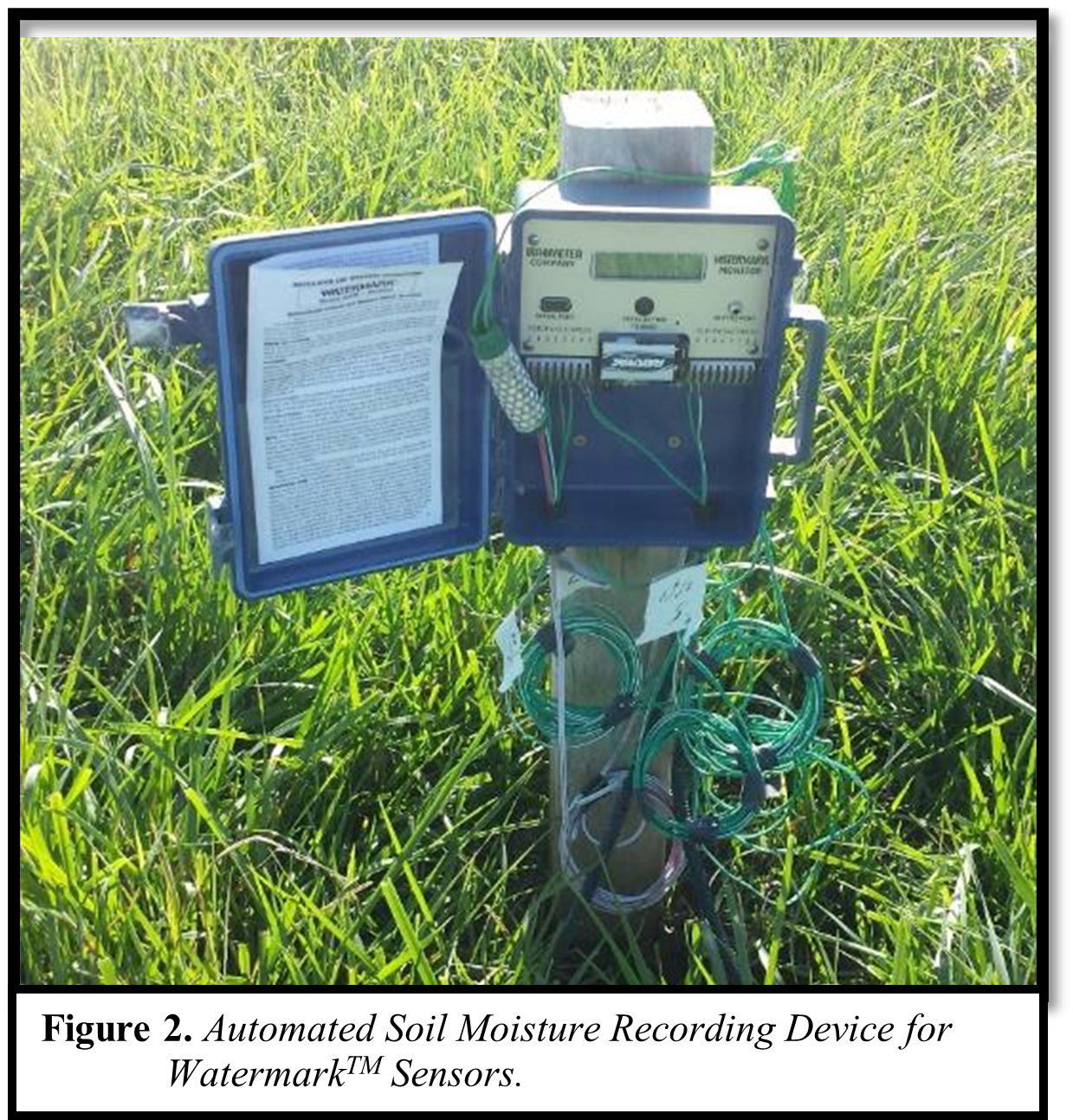

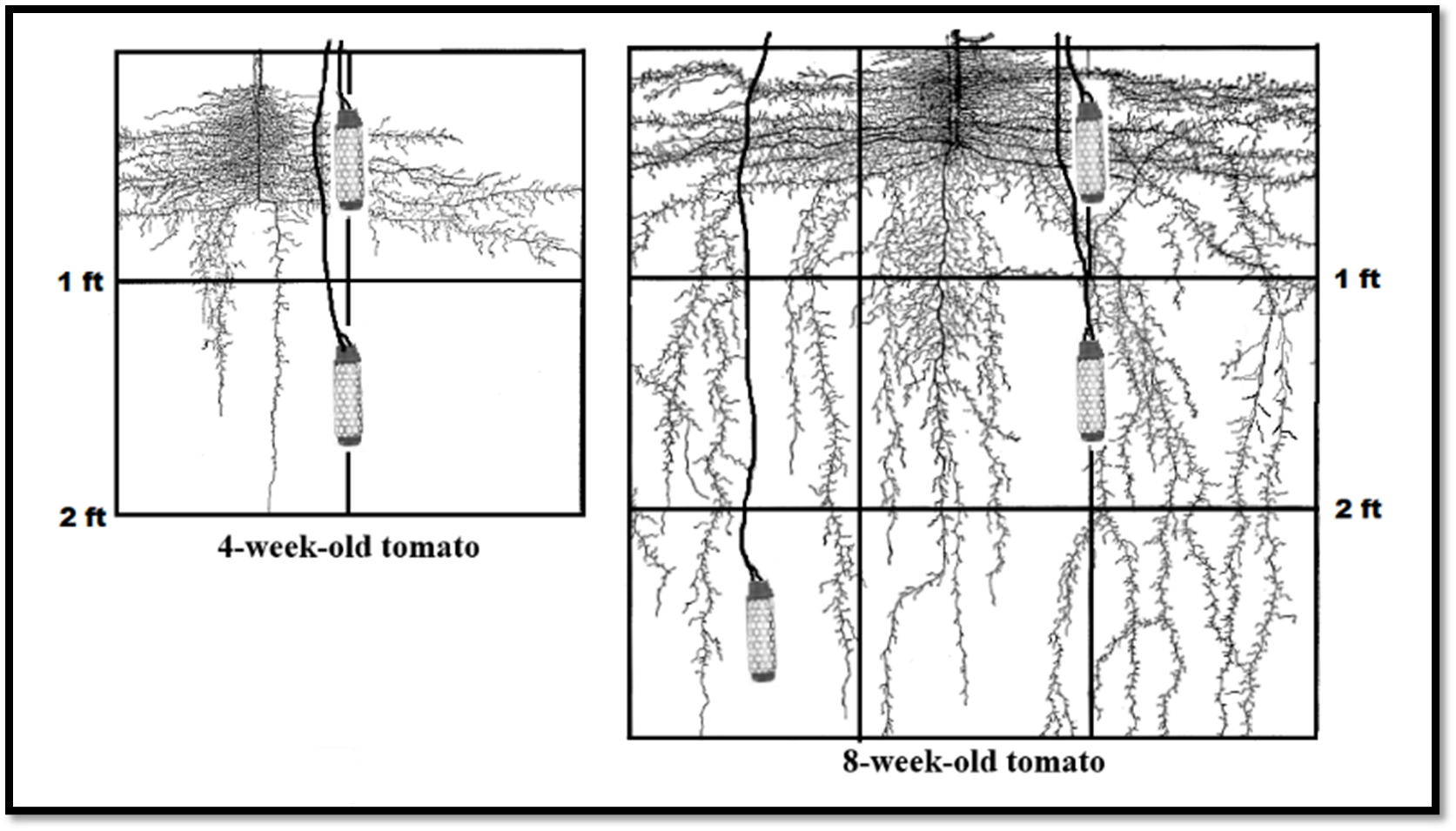

The goal of a well-managed high tunnel irrigation program is to maintain soil moisture between field capacity and the point of allowable depletion. Just like under field conditions, the easiest way to monitor soil water content is with soil moisture sensors (Figure 2). Sensors are positioned at transplanting, placed about 6 inches to the side, and used to track soil moisture throughout crop production. Sensors are installed at two depths that are specific to crop type: the minimum rooting depth and average rooting depth. For example, if the crop is early high tunnel tomatoes (Figure 3), then install the sensors 6 inches deep (minimum soil depth) and at 18–24 inches deep (near the bottom of the average rooting depth). Having a sensor at 30 inches can also be helpful to ensure the soil does not dry out or stay too wet where there are very few roots. This helps manage both under- and over-irrigation. Reference our soil moisture sensors fact sheet for more information about using sensors for irrigation management.

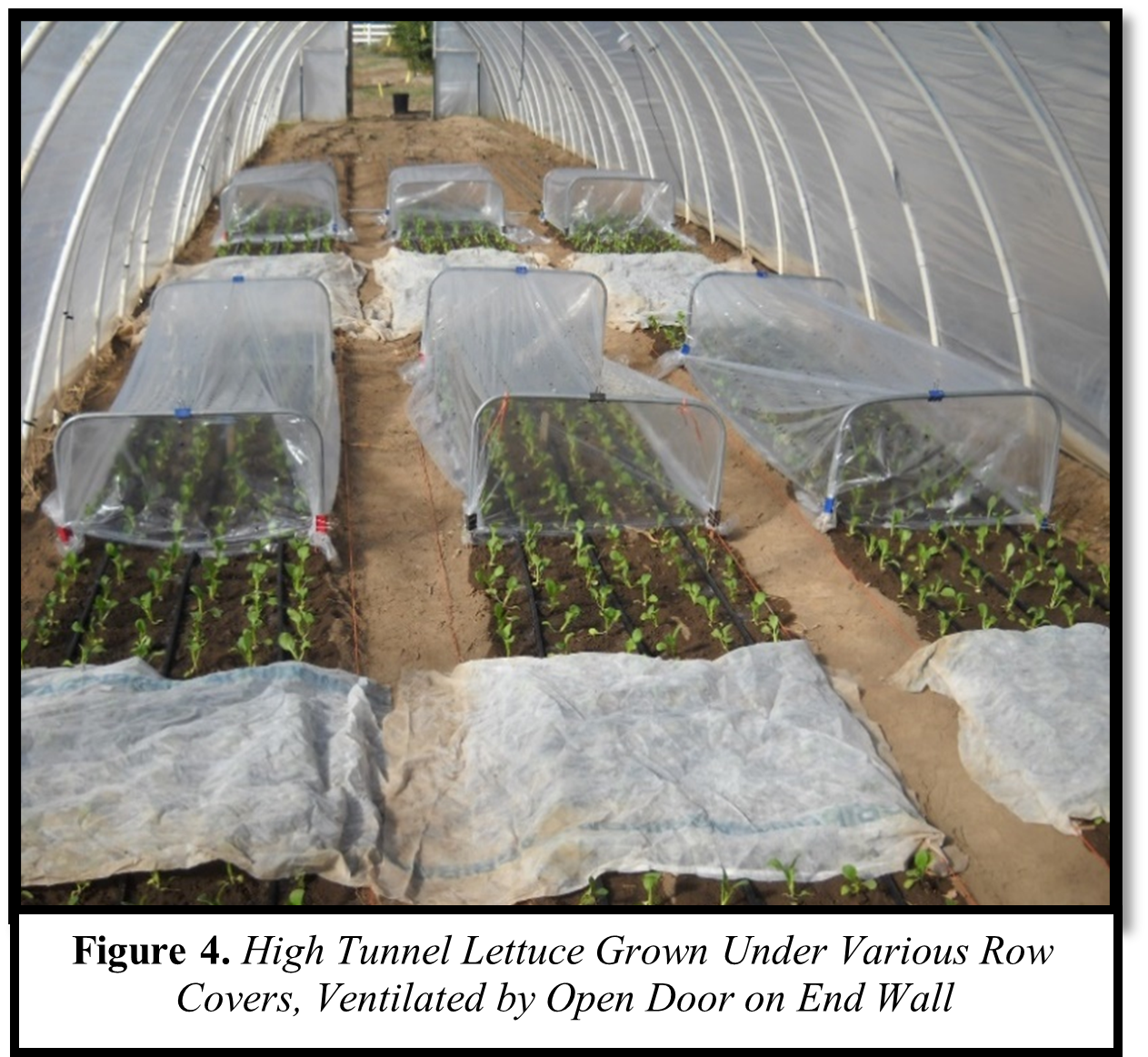

During the fall through spring, temperature management in high tunnels is regulated via ventilation using either the doors or sidewalls to change airflow and regulate humidity conditions in the tunnel. Venting a tunnel has implications for water management (Figure 4). Doors and sides may or may not be opened and closed on any given day, and this changes a plant’s water use. Furthermore, plants may be covered with low tunnels and/or floating row covers (Figure 4) or be grown on plastic mulches (Figure 5). Supplemental soil and/or air heating may also be used, which increases plant water use. Later in the spring, the tunnel plastic may be removed and replaced with shade cloth. All of these affect the amount of water that plants use and make it difficult to schedule irrigation applications on a programmed (set) schedule. Thus, without monitoring soil moisture, it is easy to over- or under-irrigate the crop.

Irrigation Scheduling

To successfully schedule the irrigations needed to optimize plant growth in a high tunnel, you need to know (1) the value of field capacity for the soil type; (2) the allowable depletion for that soil; (3) how much water plants use (how much water is needed); and (4) the output of your irrigation system (how much water to apply). Since water loss is related to runoff, deep drainage, evaporation from the soil surface, and transpiration by the plants, a good understanding of each will help regulate water replacement needs in the tunnel. Since most tunnels are located on flat land, runoff is usually minor. In addition, deep drainage may be ignored, provided the high tunnel is not over-irrigated. Therefore, evaporation and transpiration are the key drivers of water use in the tunnel.

One effective and reliable method for measuring soil moisture is with an electrical resistance block, such as the WatermarkTM sensor (Irrometer Co., Riverside, CA). These blocks are installed in the soil after planting and used to track changes in electrical resistance. The resistance measurements are then related to soil water potential, an indicator of how hard the plant roots have to “pull” to obtain water from the soil or how tightly the soil hangs onto water. The measuring device estimates soil water potential in centibars (cb). Soil water potential values from 0–10 cb indicate a soil is nearly saturated, while a value of 10–30 cb, depending on soil type, approximates field capacity (Figure 6). Higher values indicate the soil is drying down and there is less available water. For most soils and crops grown in a high tunnel, it is recommended to keep the soil water potential below 80 cb. With a sensor located at the minimum and average depths for the crop being grown (Table 1), you can then identify when irrigations are required at any time of the year.

Key Steps to Follow

The key to proper irrigation scheduling and management comes from understanding the relationship between soil type, available depletion, and soil moisture sensor values (Figure 6). Use the following steps (and see the case study example).

Step 1:

Determine the soil type for the tunnel. Establish the soil types from the routine soil test conducted by a reputable soil testing service (http://www.usual.usu.edu/), by downloading the free SoilWeb app (from the App Store), or by using the USDA-Natural Resources Conservation Service Web Soil Survey found on-line (https://websoilsurvey.sc.egov.usda.gov/App/HomePage.htm). Not all soil types are noted in Table 2, but one can approximate the available water depletion for other soil types to help estimate changes.

Step 2:

Use Figure 6 to find the field capacity value by following down the 10% available water depletion line to where it crosses the soil type line. Follow this to the left axis (soil suction) to determine the reference value that approximates field capacity.

Step 3:

Select the appropriate allowable depletion percentage for the crop being grown. If the crop has a 50% allowable depletion, follow that value down to the high tunnel soil type and then go over to the soil suction axis to obtain the sensor value (Figure 6). This value indicates when you should irrigate without creating water stress that may impact plant growth. For example, in the high tunnel research block at the Utah State University (USU) Greenville Farm, the soil type is a Millville silt loam. For fall lettuce, irrigate when the soil reaches 40% allowable depletion (soil suction value = 100 centibars). Since depletion values vary, better irrigation scheduling will occur by tracking the soil moisture levels.

Step 4:

Keep a log of changes in WatermarkTM sensor values and record these daily. In the spring, values can change rapidly as both daily temperature and light levels increase, which causes larger increases in plant water use. In the autumn, as daily temperatures and light levels decrease, daily water use goes down, and thus, the irrigation interval will also change. In winter, irrigations may be required depending on conditions in the high tunnel. Without some way to monitor soil moisture, one cannot be sure if irrigations are needed or not. Growers that are first adapting their management practices to high tunnels often err on the side of overwatering, which creates problems. Automated monitoring systems are available (Figure 2), which routinely record soil moisture readings. Automation provides a permanent record of the soil moisture profile over time, and evaluating the data can determine ways to improve irrigation scheduling. Step 5:

Irrigate to replace soil water used by the plants and recharge the soil to field capacity. Drip irrigation is a highly efficient irrigation method well suited to flowers, fruits, and vegetables grown in high tunnels. Find details on using drip irrigation in flower, fruit, or vegetable production systems at https://extension.usu.edu/productionhort/vegetables/irrigation.

Changes in the internal microclimate of the high tunnel have a significant effect on irrigation requirements. Some growers prefer to leave the plastic on a high tunnel during the summer. Conditions in the tunnel are often much hotter than outside due to the restricted airflow, and plants often experience high moisture stress conditions. Plants may wilt (show moisture stress) even if soils are well watered. If the plastic is left on the tunnel during the summer, there is an increased need for irrigation, and more regular checks of soil moisture are needed. In the late fall, during the cold winter, or as temperature conditions improve in early spring, high tunnels can experience high humidity, which can reduce or alter irrigation needs. During these periods, tunnels are not always ventilated adequately as the grower attempts to increase tunnel temperatures to enhance plant growth. Pay attention to leaf wetness (condensation) and carefully monitor soil moisture to avoid disease development during these times. Irrigation requirements, which are frequent in summer, may only be monthly during the middle of winter.

Summary

High tunnel irrigation management requires knowledge of the following concepts:1. Differences in soil water holding capacity.

2. Variances in plants rooting depth.

3. How changing environmental conditions impact plant water use.

4. Proper water application, which is based on:

- a. Soil water-holding capacity.

- b. Seasonal needs differences.

- c. Soil water monitoring.

- d. Knowledge of irrigation system operations.

- e. Good record keeping.

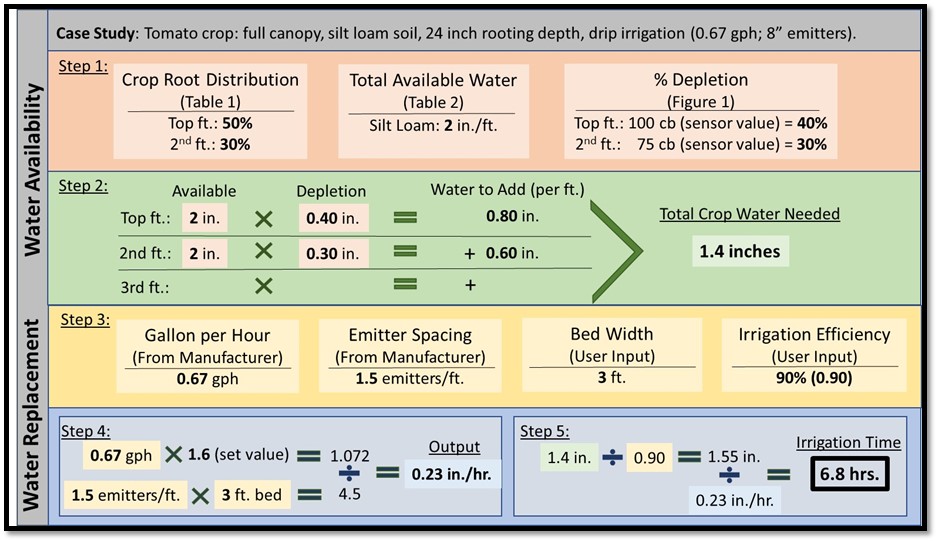

Case Study

Use the following example to help calculate water replacement needs for high tunnel tomatoes. The example is for a crop with a full canopy (100% ground cover) in June. The soil is a deep silt loam, crop-rooting depth of 24 inches, drip irrigated, 3-foot bed centers, with plastic mulch. Additional information needed is drip tape output and emitter spacing.

Step 1: Water Availability – Gather information on soil type and total available water (Table 2). Determine crop root distribution (Table 1; Figure 3). Identify percent (%) depletion for root zones (Figure 6).

Step 2: Crop Water Needs – Use data from Step 1 to calculate total crop water need to recharge the soil profile.

Step 3: Additional Data – Identify drip tape output (gallons per hour), drip emitter spacing, crop row spacing, and irrigation system efficiency. Drip tape emitter spacing is commonly noted as "inches." For example, if the tape has an 8-inch emitter spacing, this would translate to 1.5 emitters per foot (12 inches per foot/8-inch spacing = 1.5 emitters/foot).

Step 4: Drip System Water Output – Use the drip system information (Step 3) to calculate output in inches of water applied per hour. Note: The conversion from gallons per hour (gph) to inches applied per hour (in./hr.) is 1.6.

Step 5: Irrigation Run Time – Multiply total crop water need by irrigation efficiency and then divide this by output to establish the irrigation run time required to recharge soil profile.

*Disclaimers

Photographs may not be used without written permission from the authors. Pictures by D. Drost and N. Allen. The information reflects the views of the author(s). Reference to trademarked equipment is for example purposes only and is not an endorsement.

References

Maughan, T., Allen, L.N., & Drost, D. (2015). Soil moisture measurement and sensors for irrigation management. Paper 778. https://digitalcommons.usu.edu/extension_curall/778

Maughan, T., Allen, L.N., & Drost, D. (2017). Drip irrigation for commercial vegetable and fruit production. Paper 1772. https://digitalcommons.usu.edu/extension_curall/1772

Weaver, J.E. & Bruner, W.E. (1927). Root development in vegetable crops. McGraw-Hill Book Company.

Authors

Dan Drost, Brent Black, and Melanie Stock, Extension Specialists

Utah 4-H & Youth

Utah 4-H & Youth